John Wilson

Well-Known Member

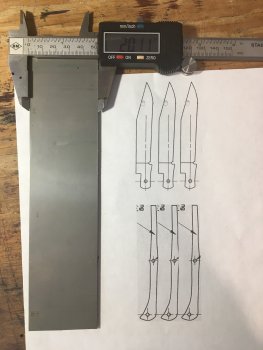

I have decided to do a slipjoint for my KITH.

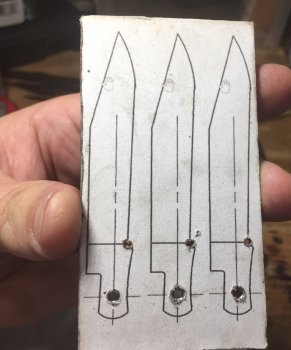

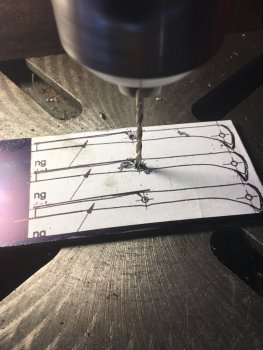

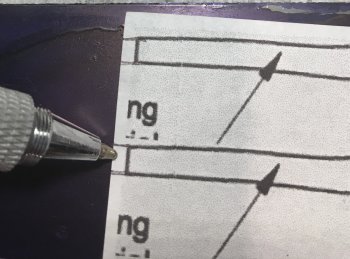

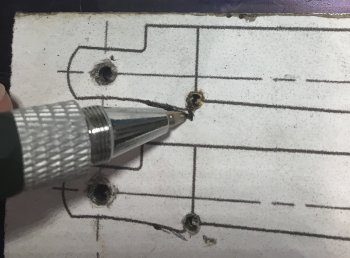

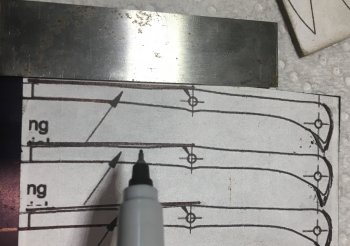

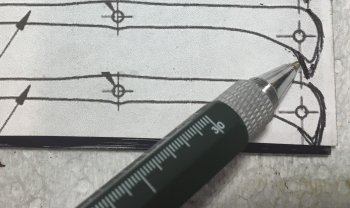

Here are some updated pics of the knife I referenced earlier. This will be the type of knife I plan to make.

It is a Don Robinson design he calls the Whittler.

Here are some updated pics of the knife I referenced earlier. This will be the type of knife I plan to make.

It is a Don Robinson design he calls the Whittler.