Mark Barone

Well-Known Member

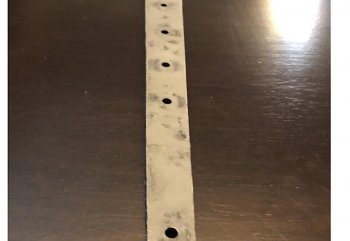

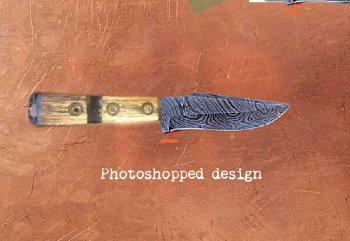

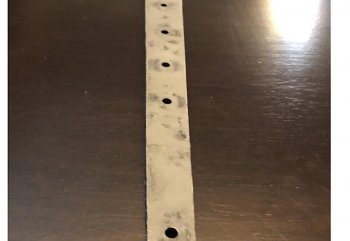

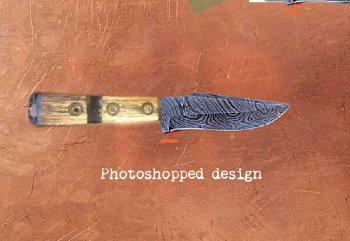

So an Air Force veteran wants me to make a knife using the titanium wing skid plate of a military spy plane. My thoughts are to cut it in half incorporate and use as the scales of the knife. I will use the already drilled holes for the pin. It’s a bit narrow so maybe I need to add resin or border with exotic wood. I’m not sure yet until I get it. Will I have a problem cutting it with my portaband? Can it be shaped a little with a belt sander? I have never cut titanium before. It is going to be a display knife.