Edwardshandmadeknives

Well-Known Member

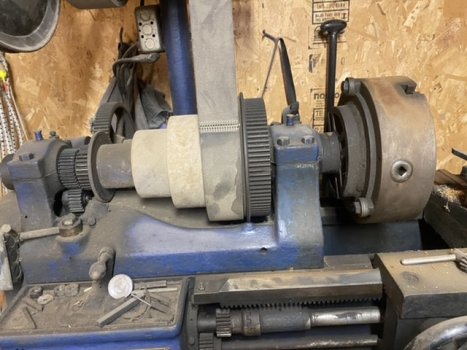

I have an old Flather lathe from I believe 1906. It’s a pretty good lathe, but the bearings are really bad. I’m guessing that they are babbit bearings. I haven’t ever done babbit bearing replacement before. Is it ok to start taking it apart, or is there stuff I should do before hand? Any good videos on something like that? I’ve looked at some on YouTube but some are quite different from others, so I don’t know how great my information is. I would actually like to replace them with bearing bronze if they are babbit.