Diamond G Knives

Well-Known Member

Needing to have some CAD drawings done for some of my designs. Anyone here have the ability to do this? Or know of anyone that does it outsource?

Thanks, and God Bless

Mike

Thanks, and God Bless

Mike

I'm needing to do something similar. I do my designs in neu.draw on my iPad and can export them as a PDF. Is there a free and reliable way to convert them to dxf for laser cutting?

Thanks

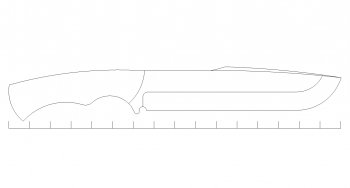

Any program that can export dxf should work. Not to pick on Mike, or Duncan's drawings, but do NOT send a drawing like that to your cutter. No details like handles, bolsters, or grind lines. No little accidental pieces of lines, or arcs, or any other goemetry. Only the outline, and holes that you want. They will cut every line in the drawing, and if they have to clean the drawing up you might be charged a fee.

There may also be a nesting fee when they set up the program. You might be able to get around this if you arrange your knives in a pattern to leave as little waste as possible. Leave about 3/16" between them (that is for plasma. Waterjet might be closer). I would also arrange them in a longitudinal pattern to where the grain of the steel runs the same direction in all the blades.

Bob

Any program that can export dxf should work. Not to pick on Mike, or Duncan's drawings, but do NOT send a drawing like that to your cutter. No details like handles, bolsters, or grind lines. No little accidental pieces of lines, or arcs, or any other goemetry. Only the outline, and holes that you want. They will cut every line in the drawing, and if they have to clean the drawing up you might be charged a fee.

There may also be a nesting fee when they set up the program. You might be able to get around this if you arrange your knives in a pattern to leave as little waste as possible. Leave about 3/16" between them (that is for plasma. Waterjet might be closer). I would also arrange them in a longitudinal pattern to where the grain of the steel runs the same direction in all the blades.

Bob