You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Budden

- Thread starter opaul

- Start date

C Craft

Well-Known Member

congrats on the baby!! Since you titled this Budden I am gonna assume you are speaking of a Hay Budden! What weight is she!! It looks good flat top and real good edges! I got a Hay Budden of my own! I had some down time recently so I did a little research on it and decided to fill in a few blanks!!

I believe your edges may be a bit truer/squarer/crisp, than mine. Someone rolled the edges on it before I got it. Mine weighs in at 143 lbs.

I believe your edges may be a bit truer/squarer/crisp, than mine. Someone rolled the edges on it before I got it. Mine weighs in at 143 lbs.

Gliden07

Well-Known Member

I'm collecting my items to forge next Spring. I have a friend that is gonna help me out but I plan on taking a class too!

opaul

Well-Known Member

Thanks guys. Now come over and help me get it out of the truck!

Seriously, I'm going to get my two son-in-laws over and get them to move it for me. I'm thinking slinging it between a couple of two by fours so they can lift it and carry it safari style.... I'll be watching . Any other suggestions?

. Any other suggestions?

It also came with a cut off hardy tool (wedged shape). Then on to build a stand and get it set up. The school that I went to is making a really cool forge set up , I'd really like to get one when I get my shop ready for something like this. If you have any questions let me know about how it works.

Seriously, I'm going to get my two son-in-laws over and get them to move it for me. I'm thinking slinging it between a couple of two by fours so they can lift it and carry it safari style.... I'll be watching

It also came with a cut off hardy tool (wedged shape). Then on to build a stand and get it set up. The school that I went to is making a really cool forge set up , I'd really like to get one when I get my shop ready for something like this. If you have any questions let me know about how it works.

Last edited:

EdCaffreyMS

"The Montana Bladesmith"

SUPER! I can't see the face in the pic, but probably the best thing I've ever done was to have the face of my #300 Trenton machined/refaced...... getting rid of the dents and dings in an anvil's face makes thing so much nicer and easier when forging.

I'm pretty anal when it comes to the faces of my anvils..... I try to keep them to as close to a mirror finish as I can. Every time I have a student in the shop, they are briefed to treat the face of my anvils "like their made of glass".

I'm pretty anal when it comes to the faces of my anvils..... I try to keep them to as close to a mirror finish as I can. Every time I have a student in the shop, they are briefed to treat the face of my anvils "like their made of glass".

opaul

Well-Known Member

At some point I may. It was really interesting and in using the coal/coke forge.Your gonna go with a Coal forge?

EdCaffreyMS

"The Montana Bladesmith"

If you don't already have a source for coal/coke...... just be aware that "good" forging coal makes ALL the difference. Way back when I was using coal, I purchased from Cumberland/Elkhorn out of Louisville, KY. It was the best forging coal I ever found. When we moved to Montana, I searched everywhere west of the Mississippi, and could not find any forging coal that came close to the Cumberland/Elhorn..... having it shipped was not economical ($250 per ton for the coal, and $600+ to have it shipped to Montana)... which is when I made the switch to propane forges.

The Cumberland/Elkhorn mine was/is located in West Virginia, so you may have somewhere closer then Louisville that has it.

The Cumberland/Elkhorn mine was/is located in West Virginia, so you may have somewhere closer then Louisville that has it.

opaul

Well-Known Member

I may go with a larger gas forge, but I have plenty of time to decide.

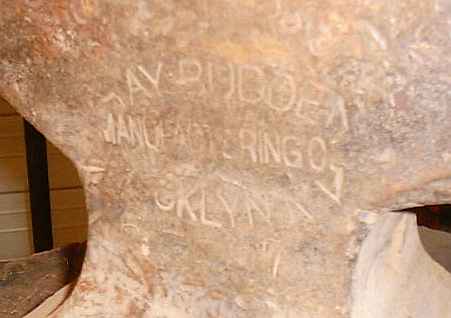

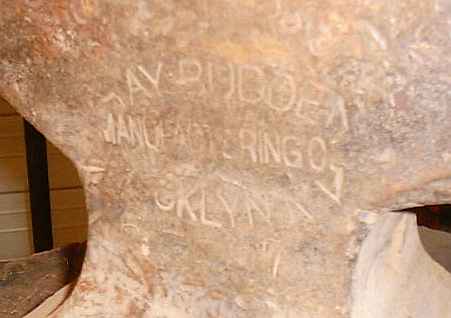

I did some wire brushing and although the markings are hard to see it is a 204 lb. Hay Budden serial number A259XX I can't decipher the last numbers. This thing is heavy. I did get it out of my truck by myself just now and stored until a have a spot set up to mount it.

Here she is in the sunshine.

I did some wire brushing and although the markings are hard to see it is a 204 lb. Hay Budden serial number A259XX I can't decipher the last numbers. This thing is heavy. I did get it out of my truck by myself just now and stored until a have a spot set up to mount it.

Here she is in the sunshine.

C Craft

Well-Known Member

You would have thought they would have marked them better. I could only see some of what was on mine! After doing the research on it I used what I could see and from pics of I re-created the full lettering and hand painted the logo and weight mark on it!! Don't ask me why, because it don't make the anvil any better but, I like history. This is a way of preserving some of the history!

Here are a couple of links to another forum and a thread where a lot of the history of Hay Buddens was discussed!

https://www.bladesmithsforum.com/index.php?/topic/34222-questions-about-hay-budden-anvils/

https://www.bladesmithsforum.com/in...budden-pic-heavy/&tab=comments#comment-333098

Alan Longmire and Geoff Keyes from that forum are both very knowledgeable about anvils. Alan has access to the serial numbers which can pretty much nail down the date of the anvil. However there are three different markers, that also can help to date a Hay Budden. Some had a steel plate on top about 3/4" thick, others appear to have a steel top that goes about halfway down the anvil and they were married together as the anvil was cast and the other has a steel plate about 1 1/2" - 2" thick on it! I first thought mine was one of those with a 3/4" steel plate, however while painting it I hit the anvil with a haze coat, sorta a primer coat and the line where the top half of the anvil was married to the bottom mild steel base shows well. I think it is one of the photos of those links!! Anyway it indicates that mine was made after 1914. The 3/4" face was done till 1914 and after that date they were married at the halfway point!!

Hay Budden also changed its logo several times. One is the arched like is on mine. Some were straight! Others had the New York spelled out some had only NY. Here are some pics of different logos!

Here is a Hay Budden with the top plate shows as it has been broken

This one is one of the most pristine logo's I remember seeing!

Here is one with an entirely different logo.

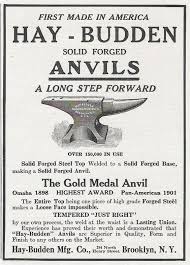

And finally one of the coolest things I have seen. A copy of an old Hay Budden advertisement!

Oh and I forgot this one, it one of the biggest I have ever seen! If you look closely in this pic you can see where someone marked the marry line with chalk! I can't make out the weight but, I think it may be a 856. If is is that is a whopper!!!

Take a look at this baby!!! Actually that is a sheet metal anvil made to set out in front of a blacksmith's shop! LOL

Dan Boone, George Smart and Mike Tanner with the sheet metal "anvil" sign

Dan Boone, George Smart and Mike Tanner with the sheet metal "anvil" sign

Here are a couple of links to another forum and a thread where a lot of the history of Hay Buddens was discussed!

https://www.bladesmithsforum.com/index.php?/topic/34222-questions-about-hay-budden-anvils/

https://www.bladesmithsforum.com/in...budden-pic-heavy/&tab=comments#comment-333098

Alan Longmire and Geoff Keyes from that forum are both very knowledgeable about anvils. Alan has access to the serial numbers which can pretty much nail down the date of the anvil. However there are three different markers, that also can help to date a Hay Budden. Some had a steel plate on top about 3/4" thick, others appear to have a steel top that goes about halfway down the anvil and they were married together as the anvil was cast and the other has a steel plate about 1 1/2" - 2" thick on it! I first thought mine was one of those with a 3/4" steel plate, however while painting it I hit the anvil with a haze coat, sorta a primer coat and the line where the top half of the anvil was married to the bottom mild steel base shows well. I think it is one of the photos of those links!! Anyway it indicates that mine was made after 1914. The 3/4" face was done till 1914 and after that date they were married at the halfway point!!

Hay Budden also changed its logo several times. One is the arched like is on mine. Some were straight! Others had the New York spelled out some had only NY. Here are some pics of different logos!

Here is a Hay Budden with the top plate shows as it has been broken

This one is one of the most pristine logo's I remember seeing!

Here is one with an entirely different logo.

And finally one of the coolest things I have seen. A copy of an old Hay Budden advertisement!

Oh and I forgot this one, it one of the biggest I have ever seen! If you look closely in this pic you can see where someone marked the marry line with chalk! I can't make out the weight but, I think it may be a 856. If is is that is a whopper!!!

Take a look at this baby!!! Actually that is a sheet metal anvil made to set out in front of a blacksmith's shop! LOL

Last edited:

opaul

Well-Known Member

WOW! thanks C Craft that is a wealth of information. My markings are more in line with picture you posted up and funny because mine is a 204 pounder also. I can make out the HA and then a B, where is says Manufacturing - it's legible as well as Brooklyn NY.

I'm thinking but haven't confirmed mine is probably a 1920's era model. Unbelievable that they are still around but they are beasts indeed!

The pictures you posted are most helpful.

thank you!

I'm thinking but haven't confirmed mine is probably a 1920's era model. Unbelievable that they are still around but they are beasts indeed!

The pictures you posted are most helpful.

thank you!