Kayakersteve

Well-Known Member

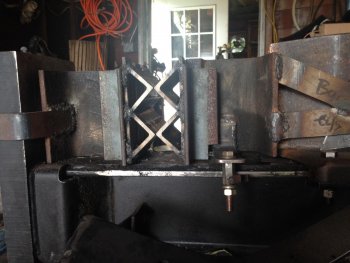

Started with mild tube 3x3 Coated with white out - Added 1084 powder and 1/2" ball bearings - Pressed well and billet stayed separated from tube as planned. Looked so so when first out of canister, but was able to recover it or so I thought. As I began to draw out, it quickly became clear I had a failure that was not recoverable. Now the question is what might I have done wrong on my first attempt at this? My guess is it has to do with the ball bearings -- they were purchased from Amazon....could they have contained junk steel? The billet has a bronze look to it making me think some junk steel or cast something was present. Any thoughts????

Attachments

-

cannister weld e.JPG68.6 KB · Views: 24

cannister weld e.JPG68.6 KB · Views: 24 -

cannister weld f.JPG40.7 KB · Views: 25

cannister weld f.JPG40.7 KB · Views: 25 -

cannister weld g.JPG24.1 KB · Views: 26

cannister weld g.JPG24.1 KB · Views: 26 -

cannister weld h.JPG78.3 KB · Views: 25

cannister weld h.JPG78.3 KB · Views: 25 -

cannister weld i.JPG60.9 KB · Views: 24

cannister weld i.JPG60.9 KB · Views: 24 -

cannister weld j.JPG137.9 KB · Views: 24

cannister weld j.JPG137.9 KB · Views: 24 -

cannister weld c.JPG135.2 KB · Views: 32

cannister weld c.JPG135.2 KB · Views: 32 -

cannister weld b.JPG132.6 KB · Views: 29

cannister weld b.JPG132.6 KB · Views: 29 -

cannister weld A.JPG126.2 KB · Views: 24

cannister weld A.JPG126.2 KB · Views: 24