Entropy762

Well-Known Member

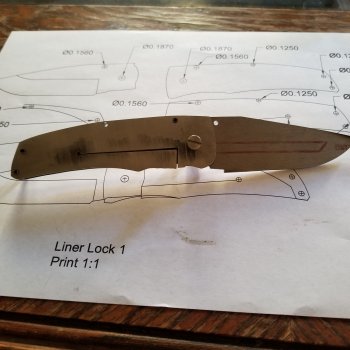

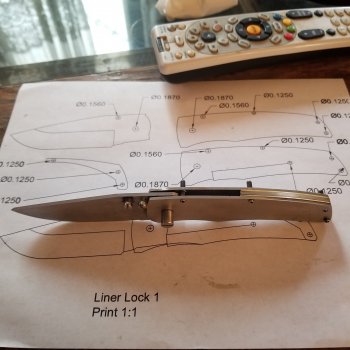

Well after messing around with the Draftsight CAD program I came up with a rough design for a liner lock. The blade is O1 and still needs work. The liners are from a sheet of SS I got at work. Unfortunately it seems non heat treatable so I have come up with a way to lock the blade open. This is the first time going from CAD to cutting steel. It's a fun process.

Jake

Jake