Austin Thrasher

Well-Known Member

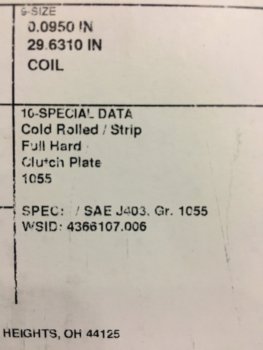

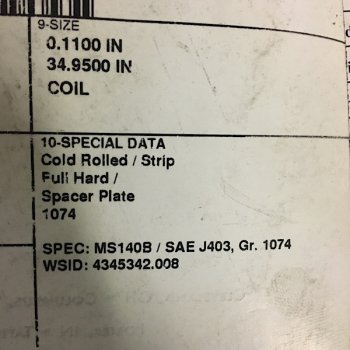

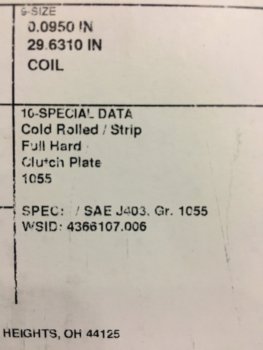

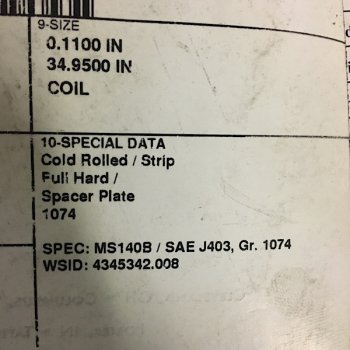

Ok guys I’m a bit excited about this. I work in a tool and die shop that makes and services stamping dies for the automotive industry. To cut to the chase here, I just found out today that some of the steel we stamp is 1055 and 1074! Now, I (think I) understand that 1055 is decent knife steel for high impact blades like kukris, machetes, parangs, etc. Am I correct on that? Also I do not know about 1074. I’ve seen 1075 used for knives before but not 1074. Anyone have an opinion on those steels? What are they used for? Is it even worth pursuing? The coils run through a flattener that gets the steel fairly flat and I would be keeping the scrap skeleton that gets chopped off after the part is stamped. Literally tons of it gets thrown away or scrapped every day. Any feedback would be greatly appreciated!