You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Glass platen?

- Thread starter 52 Ford

- Start date

CDHumiston

KNIFE MAKER

I have a glass platen add-on...can't comment on ceramics, but the glass seems to work.

Edwardshandmadeknives

Well-Known Member

My brother has a glass platen on his grinder at home, it’s part of a fireplace door stuck to the metal platen with double sided alien tape. Ceramic is a little tougher than glass, not sure if it will handle temp changes the same though. I bet it would work fine

52 Ford

Well-Known Member

I might give it a try. I don't think the temperature change would be rapid enough to crack the ceramic. Right now on my 4" sander, I have a piece of leather covered in aluminum tape on the platen to give me some more give. I was blending some faces together. Honestly, it took 20+ minutes with a LOT of pressure on the belt to get it hot. No real wear to the aluminum tape and it's been on there for over a month.

This is way overkill, but whenever I get around to my BIG belt grinder build with a 8 or 10 inch belt, I'm going to use a piece of granite countertop for the platen. I just happen to have a big stack of granite countertop cutouts.

Sent from my Champion Forge using Tapatalk

This is way overkill, but whenever I get around to my BIG belt grinder build with a 8 or 10 inch belt, I'm going to use a piece of granite countertop for the platen. I just happen to have a big stack of granite countertop cutouts.

Sent from my Champion Forge using Tapatalk

John Wilson

Well-Known Member

I have heard of a number of guys using ceramic tile. 1/4" pyroceramic (fireplace glass) is the norm. I think Boss sells common sized ones here on the site (USA Knifemaker). I took dimensions off my platen and went down to the local glass shop and told them I wanted a piece of 1/4" fireplace glass to fit it, and they cut it on the spot for about $20 if I recall. It's been several years and I'm due for a replacement.

Adding a glass platen makes a night and day improvement to the smoothness of your bevels. My first platen (bare steel) lasted about one half of a farting spell before it got grooved and dished out and needed to be replaced. My first glass platen lasted about 4 years and I think this last one has been on there for five. Adding a glass platen is a total no-brainer. I don't know why anyone even sells a flat platen without glass anymore. It has become the standard.

The question of mounting the glass always comes up. Some guys build a shelf, me- I'm lazy. I mix up a batch of JB Weld and lay it on the glass like a six year old making a peanut butter sandwich. I have never had the glass ever come loose.

Pro tip: don't forget to put your platen mounting bolts in the platen so that the JB Weld doesn't ooze up and fill the holes. Ask me how I know. And the second time you do it, makes sure you remember to put some grease on the bolts so that they don't bond in the holes...

Adding a glass platen makes a night and day improvement to the smoothness of your bevels. My first platen (bare steel) lasted about one half of a farting spell before it got grooved and dished out and needed to be replaced. My first glass platen lasted about 4 years and I think this last one has been on there for five. Adding a glass platen is a total no-brainer. I don't know why anyone even sells a flat platen without glass anymore. It has become the standard.

The question of mounting the glass always comes up. Some guys build a shelf, me- I'm lazy. I mix up a batch of JB Weld and lay it on the glass like a six year old making a peanut butter sandwich. I have never had the glass ever come loose.

Pro tip: don't forget to put your platen mounting bolts in the platen so that the JB Weld doesn't ooze up and fill the holes. Ask me how I know. And the second time you do it, makes sure you remember to put some grease on the bolts so that they don't bond in the holes...

Last edited:

52 Ford

Well-Known Member

One of the things I like about the ceramic tile is that the back is rough, so the adhesive has something to grab hold of.I have heard of a number of guys using ceramic tile. 1/4" pyroceramic (fireplace glass) is the norm. I think Boss sells common sized ones here on the site (USA Knifemaker). I took dimensions off my platen and went down to the local glass shop and told them I wanted a piece of 1/4" fireplace glass to fit it, and they cut it on the spot for about $20 if I recall. It's been several years and I'm due for a replacement.

Adding a glass platen makes a night and day improvement to the smoothness of your bevels. My first platen (bare steel) lasted about one half of a farting spell before it got grooved and dished out and needed to be replaced. My first glass platen lasted about 4 years and I think this last one has been on there for five. Adding a glass platen is a total no-brainer. I don't know why anyone even sells a flat platen without glass anymore. It has become the standard.

The question of mounting the glass always comes up. Some guys build a shelf, me- I'm lazy. I mix up a batch of JB Weld and lay it on the glass like a six year old making a peanut butter sandwich. I have never had the glass ever come loose.

Pro tip: don't forget to put your platen mounting bolts in the platen so that the JB Weld doesn't ooze up and fill the holes. Ask me how I know. And the second time you do it, makes sure you remember to put some grease on the bolts so that they don't bond in the holes...

I wonder how well that granite platen is going to hold up on my big grinder. If it wears to the point I need to fix it, I guess I'd have to lap it with a cast iron surface plate. I'm thinking the platen is going to be 8X30 or so.

Sent from my Champion Forge using Tapatalk

John Wilson

Well-Known Member

I can only guess, but I’d expect that granite to last years.

MTBob

Well-Known Member

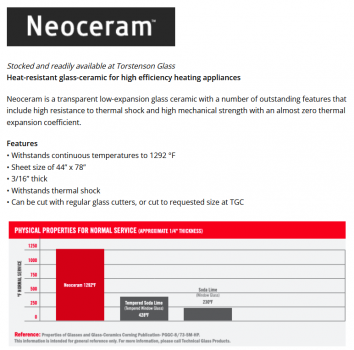

This posting has caused me to want to get a glass platen. I wasn't sure what the differences were between regular glass, tempered glass, or the "Ceramic Glass" that knife suppliers sell. So with a bit of digging I found that most knife suppliers offer ceramic glass for grinder platens and it's called NeoCeram - used on fireplace doors. I called my local glass shop and found out they can cut this stuff to fit what ever I need. A 2"x9x3/16"" piece costs $11.00.

Here's a screen shot of some NeoCeram specs.

So, why mess around with any other material, when this stuff looks like it does the job nicely and is relatively inexpensive.

Here's a screen shot of some NeoCeram specs.

So, why mess around with any other material, when this stuff looks like it does the job nicely and is relatively inexpensive.

interesting question that got me looking. The glazing on a tile isn't very thick but on a mohs hardness scale it pretty tough approaching an 8. When compared to metal that's pretty hard. My concern would be wearability and smoothness of tile. Any imperfections in the tile will translate through the belt. Once you've worn through that thin layer of glazing you got very abrasive hardened clay hitting ur belt. Also concerned with being able to roll the belt over the edge. Could you dull it enough so you could radius plunges without cutting up belts

Interesting concept

Interesting concept

chrisstaniar

Well-Known Member

I've got a glass platen that I got from usaknives been on there close to 6 years now. Go JB weld!

fitzo

Well-Known Member

Regarding the glass platen static -

One can ground themselves to the grinder with one of those computer-repair-guy wrist-straps with a lead wire and a roach clip on the end to connect to ground. I've heard of guys wrapping a chain around their waist and letting it drag on the floor effectively, too. Good pirate image, there.

Another trick is to keep a spray bottle of water handy and spritz the belt when static starts tapping you.

One can ground themselves to the grinder with one of those computer-repair-guy wrist-straps with a lead wire and a roach clip on the end to connect to ground. I've heard of guys wrapping a chain around their waist and letting it drag on the floor effectively, too. Good pirate image, there.

Another trick is to keep a spray bottle of water handy and spritz the belt when static starts tapping you.

tkroenlein

Well-Known Member

What is a "roach" clip?Regarding the glass platen static -

One can ground themselves to the grinder with one of those computer-repair-guy wrist-straps with a lead wire and a roach clip on the end to connect to ground. I've heard of guys wrapping a chain around their waist and letting it drag on the floor effectively, too. Good pirate image, there.

Another trick is to keep a spray bottle of water handy and spritz the belt when static starts tapping you.

fitzo

Well-Known Member

What is a "roach" clip?

My wife said, after the post, with only a minor stink eye, "You could have said alligator clip."

I came of age in the 70s. "Roach clip" will always be first to come to mind. LOL I call hemostats roach clips, too.

tkroenlein

Well-Known Member

Lol. I couldn't resist.My wife said, after the post, with only a minor stink eye, "You could have said alligator clip."

I came of age in the 70s. "Roach clip" will always be first to come to mind. LOL I call hemostats roach clips, too.

52 Ford

Well-Known Member

LOL I thought you were serious.Lol. I couldn't resist.

Sent from my Champion Forge using Tapatalk

52 Ford

Well-Known Member

I have some ESD mats that you stand on, and ground to your work and to your wrist.Regarding the glass platen static -

One can ground themselves to the grinder with one of those computer-repair-guy wrist-straps with a lead wire and a roach clip on the end to connect to ground. I've heard of guys wrapping a chain around their waist and letting it drag on the floor effectively, too. Good pirate image, there.

Another trick is to keep a spray bottle of water handy and spritz the belt when static starts tapping you.

They're for working with really sensitive electronics.

New computers are very resistant to ESD. Shoot, professional computer builds don't wear ESD straps, anymore. More likely to brick a CPU by dropping it than zapping it cause you walked on carpet in socks.

Sent from my Champion Forge using Tapatalk

chrisstaniar

Well-Known Member

Yeah the static buildup does make things interesting. I guess I've been too lazy to try and fix it so I just tolerate it.