Eddie Mullins

Well-Known Member

I want to make my own knife and handle designs, not just copy and existing patterns and am trying to figure out the best approach to do so. I sketched out a knife Friday, and attempted to forge one Saturday. I may post some WIP pics of the process, but what I discovered was that the handle just didn't feel good in my hand, so I opted to modify the overall look of the handle for that knife.

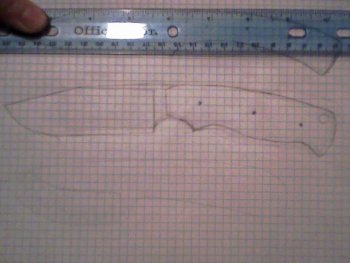

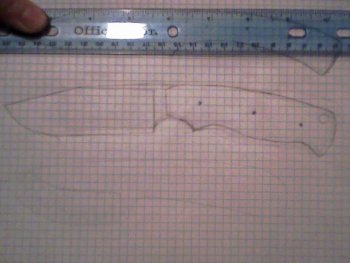

Here's the sketch in question. 4 1/4" handle , 8 1/4" overall

Today, I decided to make a wood template with a handle that fit my hand well and incorporate that into the knife for a new attempt. I did and oversized rough blank with the scroll saw and shaped to feel with the belt sander and rotary tool. Its about 1/2" shorter than the original and has a contour change. It fits quite well.

So, whats your method for designing good feeling/fitting and functional handles? Do you make wood or mock ups out of some material to check fit? Are there general proportions you use as a rule of thumb?

It now also seems to me that the ultimate custom knife would be fit to the users hand size. Do you ever do handles that are custom fit for a specific person?

And a kind of follow up question, how do you achieve the right balance between the handle and blade? Other than drilling several holes to lighten the handle, it seems that the handle to blade proportions would need to be considered in the initial design. And then what about the added weight of scales or handle materials? Is this trial and error until you figure out a design that works?

Here's the sketch in question. 4 1/4" handle , 8 1/4" overall

Today, I decided to make a wood template with a handle that fit my hand well and incorporate that into the knife for a new attempt. I did and oversized rough blank with the scroll saw and shaped to feel with the belt sander and rotary tool. Its about 1/2" shorter than the original and has a contour change. It fits quite well.

So, whats your method for designing good feeling/fitting and functional handles? Do you make wood or mock ups out of some material to check fit? Are there general proportions you use as a rule of thumb?

It now also seems to me that the ultimate custom knife would be fit to the users hand size. Do you ever do handles that are custom fit for a specific person?

And a kind of follow up question, how do you achieve the right balance between the handle and blade? Other than drilling several holes to lighten the handle, it seems that the handle to blade proportions would need to be considered in the initial design. And then what about the added weight of scales or handle materials? Is this trial and error until you figure out a design that works?

Last edited: