I am confused about what you are after.

You have mentioned 4.5 degrees, AND hollow grinding.

4.5* is pretty typical on a flat grind, but there you actually have an angle.

The relative angle between the center plane of your blade, and the bevel.

There is no such thing in a hollow grind.

That widget tells you everything that you need so you can decide if your wheel/stock combination is right for your application.

It is designed so that the tangent point of your hollow is at the edge, so yes, as with all typical grinds, the steel gets thicker from the edge to the spine.

The only way to avoid that would be to have that tangent be somewhere between the spine and the edge.

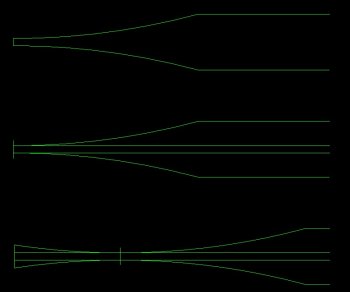

Here's a drawing to illustrate.

The top shows a section view of a hollow grind, as defined by the widget.

So does the middle, but it also has lines drawn in, representing the offset centerline planes that you defined as your .020" edge thickness, and a vertical line at the intersection of the 2.

This is what that widget tells you.

And, as you can see, the blade naturally gets thicker as you move towards the spine.

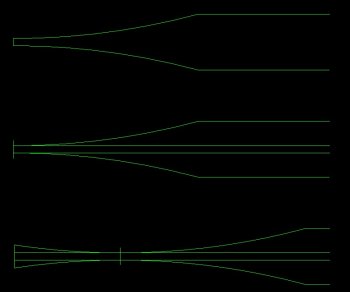

The only way you grind would get thinner behind the edge would be if you shifted that point back, like the bottom drawing.

No widget out there is going to give you numbers for that.

The trigonometry to figure it out is relatively complicated for those not well versed in the math.