ACLakey

Well-Known Member

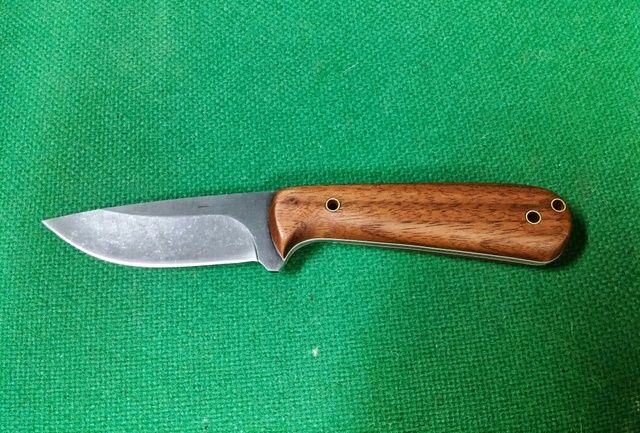

I used to make knives with my uncle twenty plus years ago and recently got interested in it again. I am looking to purchase a grinder next month and some other tools. A buddy gave me an old forge he used doing his farrier work. In the meantime, I purchased a few blanks and scales and went to work. I forgot how much I enjoyed making knifes! I am fortunate there is a custom woods supplier in town with exotics from around the world, wood options are plenty. I've enjoyed reading and learning from this forum, it's a great resource!

Here are a few weekend projects with blanks purchased online, I can't wait to start grinding my own again.

Here are a few weekend projects with blanks purchased online, I can't wait to start grinding my own again.