Johan Nel

Well-Known Member

I have seen on especially kitchen knifes, mostly the Japanese style knifes, but also a number of western types that did not have any visible plunge lines showing, and this has intrigued me quite a bit.

I had a bird and trout knife planned, and I started toying around with the idea of making it without any plunge lines. Being a total newbie in terms of knife making, and with no specific idea on how to achieve this, I had commented on one of John Wilson's threads about my idea. John gave a description of how he executes this on his kitchen knives. Dennis Morland also kindly directed me towards some youtube videos on this. Once I had viewd the videos I felt comfortable enough to try this out for myself.

First off, I need to point out that I do not have a belt grinder of any sort, but do most of the stock removal with a filing jig and hand filing.

Secondly, the blade that I am working on had some faults to it, so if I screwed this up, it would not be a train smash, but I would have gained some experience in the process.

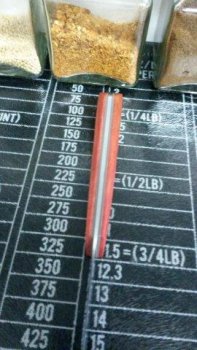

I had done the basic profiling of the blade a while ago, so what I did next was to determine the procedure to follow. I decided to determine a diagonal line across the ricasso area from the choil area to the back of the blade up to where I would file, but not beyond.

This I carefully measured out on both sides and marked out.

Once I had done that I set up the blade in the file jig and started filing away going up the blade in increments.

Constantly watching both the progess upwards to the back of the blade and towards the line I had drawn as well as the blade edge itself.

I had a bird and trout knife planned, and I started toying around with the idea of making it without any plunge lines. Being a total newbie in terms of knife making, and with no specific idea on how to achieve this, I had commented on one of John Wilson's threads about my idea. John gave a description of how he executes this on his kitchen knives. Dennis Morland also kindly directed me towards some youtube videos on this. Once I had viewd the videos I felt comfortable enough to try this out for myself.

First off, I need to point out that I do not have a belt grinder of any sort, but do most of the stock removal with a filing jig and hand filing.

Secondly, the blade that I am working on had some faults to it, so if I screwed this up, it would not be a train smash, but I would have gained some experience in the process.

I had done the basic profiling of the blade a while ago, so what I did next was to determine the procedure to follow. I decided to determine a diagonal line across the ricasso area from the choil area to the back of the blade up to where I would file, but not beyond.

This I carefully measured out on both sides and marked out.

Once I had done that I set up the blade in the file jig and started filing away going up the blade in increments.

Constantly watching both the progess upwards to the back of the blade and towards the line I had drawn as well as the blade edge itself.

Last edited: