Jason Wilder

Well-Known Member

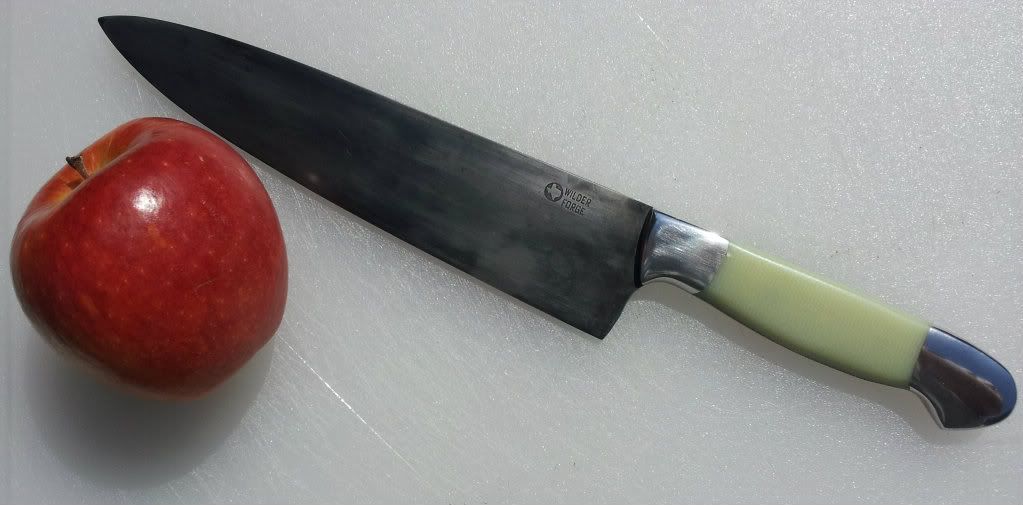

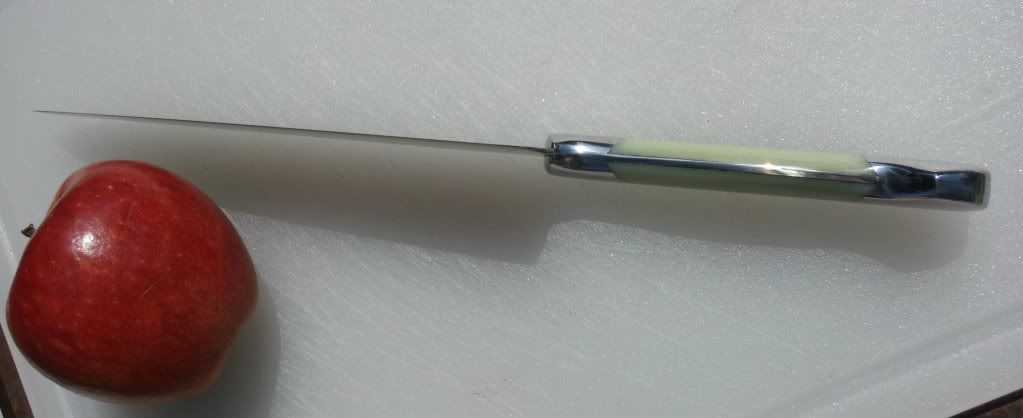

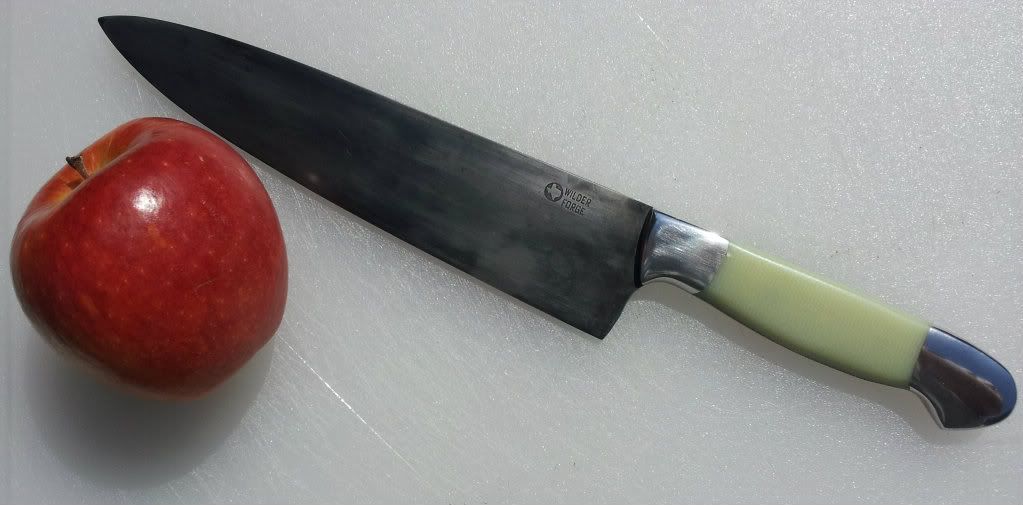

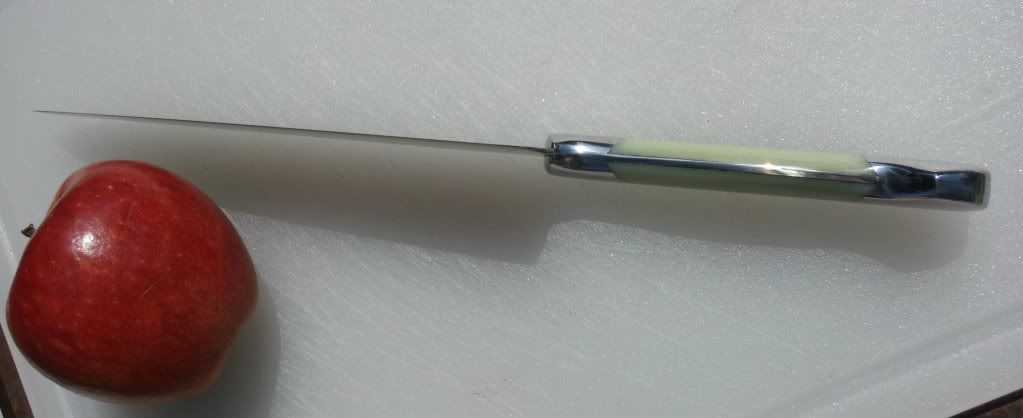

I decided to challenge myself to create a handle with no visible pins and this is what I came up with

Of course, it has pins - 7 of them: Two in each bolster and three 1/8" pins hidden 1/8" deep in the Jade G11. With the mitered (dovetail) bolsters, this handle will stay put for several lifetimes.

The blade is 8" of differentially tempered 3/32 O1.

It has a flat grind with the last 1/8" being convex grind. Then I'll finish sharpening with a V-edge. Right now, the unsharpened edge is at .007

I thought it might be a bit heavy since it has so much stainless hardware, but it weighs in at 10oz, which I think is manageable. The balance point is right at the front bolsters.

There are two areas of concern with this knife:

One is the small area of G11 near the front bolster that is discolored. I'm not sure if I hit it while peening, or what I did. It is not that noticeable, but I know it's there.

The other is the blade finish. I gave it a 600 grit hand rubbed finish before a dunk in FCL and I just can't seem to get a good uniform finish. I know part of it is due to the differential temper, but other than that, I can't figure out why it is so splotchy. It was super clean before I etched it. I'm wondering if my HT may have affected it.

I decided to try something different with the HT. I gave it a dunk in P50 then quickly put it between two ice cold plates of AL until cool. My RC tester says it is between 60-65, which is what I want since I tempered it at 400, but I just wonder if the plates made it cool unevenly?

Overall I am very pleased with the way it turned out, but I need to figure out how to have a better etched finish.

Of course, it has pins - 7 of them: Two in each bolster and three 1/8" pins hidden 1/8" deep in the Jade G11. With the mitered (dovetail) bolsters, this handle will stay put for several lifetimes.

The blade is 8" of differentially tempered 3/32 O1.

It has a flat grind with the last 1/8" being convex grind. Then I'll finish sharpening with a V-edge. Right now, the unsharpened edge is at .007

I thought it might be a bit heavy since it has so much stainless hardware, but it weighs in at 10oz, which I think is manageable. The balance point is right at the front bolsters.

There are two areas of concern with this knife:

One is the small area of G11 near the front bolster that is discolored. I'm not sure if I hit it while peening, or what I did. It is not that noticeable, but I know it's there.

The other is the blade finish. I gave it a 600 grit hand rubbed finish before a dunk in FCL and I just can't seem to get a good uniform finish. I know part of it is due to the differential temper, but other than that, I can't figure out why it is so splotchy. It was super clean before I etched it. I'm wondering if my HT may have affected it.

I decided to try something different with the HT. I gave it a dunk in P50 then quickly put it between two ice cold plates of AL until cool. My RC tester says it is between 60-65, which is what I want since I tempered it at 400, but I just wonder if the plates made it cool unevenly?

Overall I am very pleased with the way it turned out, but I need to figure out how to have a better etched finish.