J.Leclair

Well-Known Member

Hey guys, I'm currently working on my first slipjoint. I've always wanted to try to make one but have been too intimidated to try.....until now. If anyone has any tips or suggestions on how to make this easier please share.

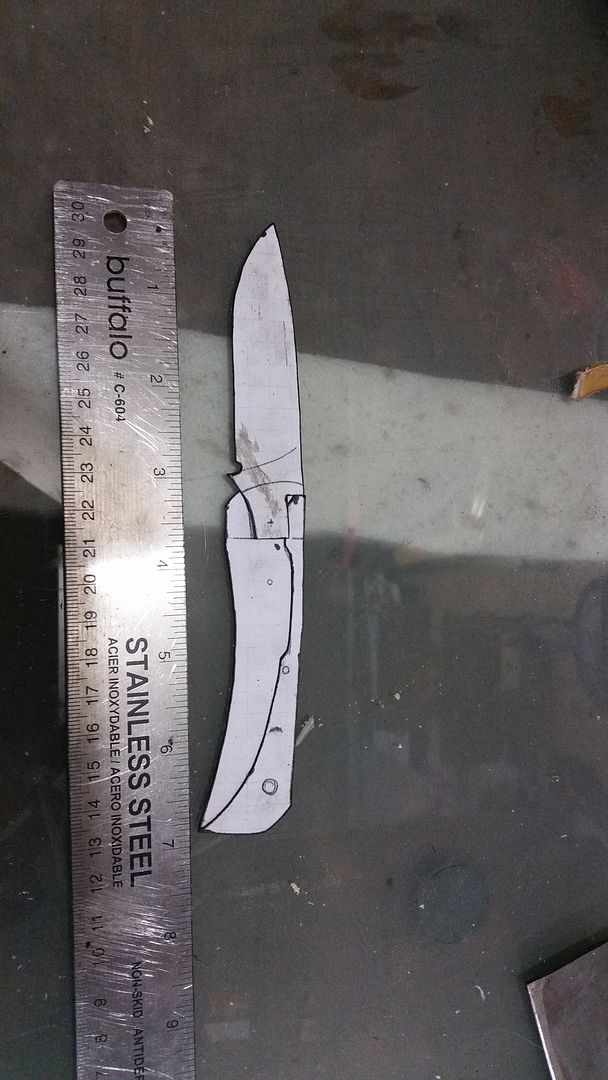

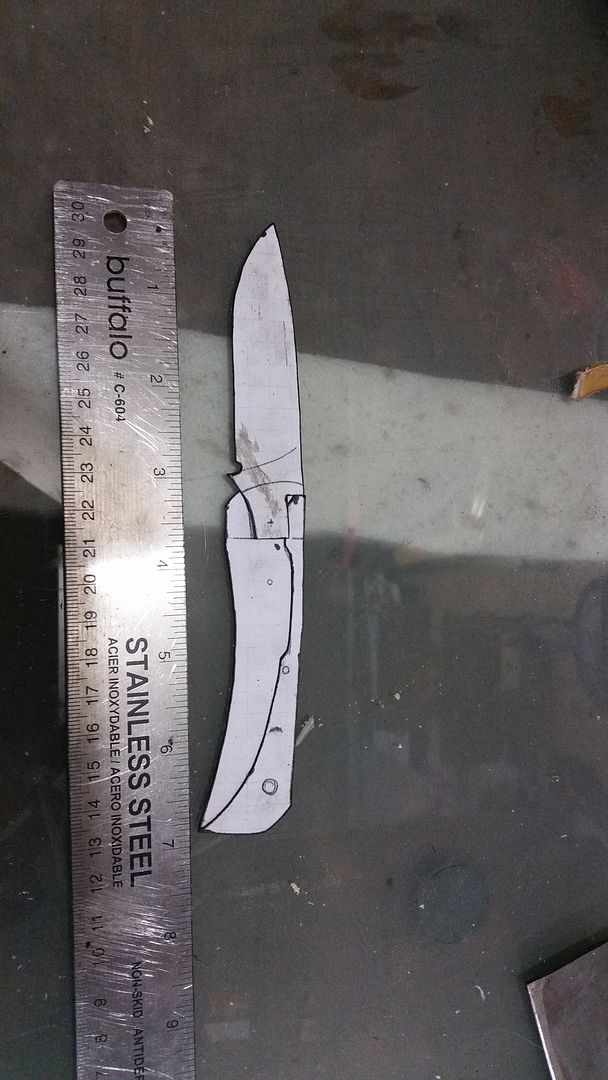

I started with some sketches that I made photocopies of and cut out the blade. Then I used a tack to find where the pivot would need to be in order to make sure the spring would be flush in all 3 stops.

Once I had my design to where I liked it I transferred it to lexan to make a reusable template.

I then cut my blade and spring from 154cm, and drilled the pivot hole in the tang, and the Centre hole in the spring. Using a piece of scrap wood I pin my blade and spring in place and drew a line along the spine of the spring. Once I had the spring returning to its start point in open and half close, I filed down the kick until it would close with the spring still flush with the line.

Finally I ground in the bevels on the blade.

This little sucker is the smallest blade I have ever ground and as it has no handle was tricky to hold while grinding. I had to pinch my grind guide with one hand while supporting/pressing it into the belt. Glad I didn't mess it up

That's all the progress I made so far.

More to come.....

I started with some sketches that I made photocopies of and cut out the blade. Then I used a tack to find where the pivot would need to be in order to make sure the spring would be flush in all 3 stops.

Once I had my design to where I liked it I transferred it to lexan to make a reusable template.

I then cut my blade and spring from 154cm, and drilled the pivot hole in the tang, and the Centre hole in the spring. Using a piece of scrap wood I pin my blade and spring in place and drew a line along the spine of the spring. Once I had the spring returning to its start point in open and half close, I filed down the kick until it would close with the spring still flush with the line.

Finally I ground in the bevels on the blade.

This little sucker is the smallest blade I have ever ground and as it has no handle was tricky to hold while grinding. I had to pinch my grind guide with one hand while supporting/pressing it into the belt. Glad I didn't mess it up

That's all the progress I made so far.

More to come.....

Last edited: