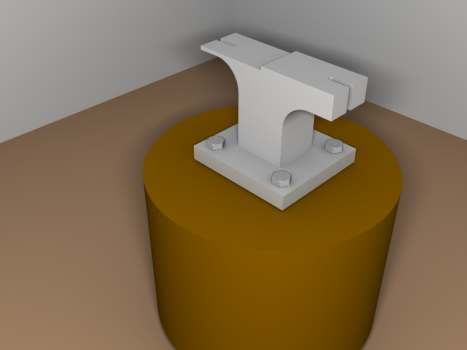

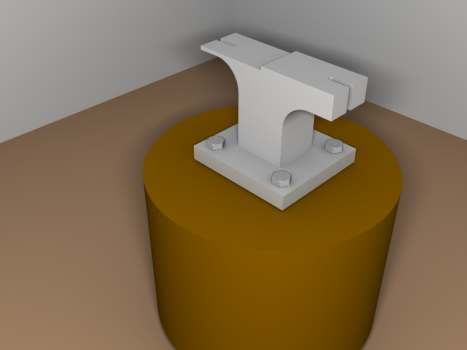

I am reading through a repair book not, and I have also seen reference to this tool in another place. They always show some sort of engineered drawing, so I thought, great I will put it in CAD.

The recommendation is always make them from some good hardenable steel. These things are 1-1/2" x 3-1/2" x 5" ... where does one get such a piece of hardenable steel? Anyway, sharing renders. I do have the CAD file, one could theoretically 3D Print these for fun. I can try to machine it, but it sounds like moving some serious metal. And I still don't understand the big curves.

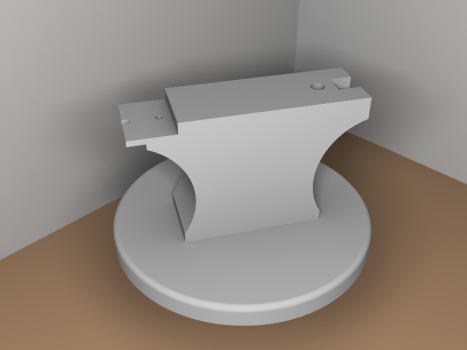

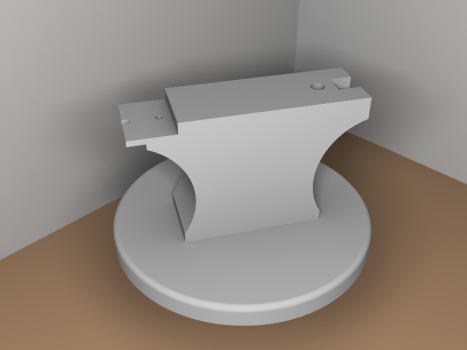

That is the Harris model. He likes holes and slots.

That is the Harris model. He likes holes and slots.

This is based on an image that keeps getting posted without attribution. I assume it is from a book, but whose? The page I keep seeing is:

... If there are other models out there that have dimensions I can try my hand at CADding them up too.

The recommendation is always make them from some good hardenable steel. These things are 1-1/2" x 3-1/2" x 5" ... where does one get such a piece of hardenable steel? Anyway, sharing renders. I do have the CAD file, one could theoretically 3D Print these for fun. I can try to machine it, but it sounds like moving some serious metal. And I still don't understand the big curves.

That is the Harris model. He likes holes and slots.

That is the Harris model. He likes holes and slots.This is based on an image that keeps getting posted without attribution. I assume it is from a book, but whose? The page I keep seeing is:

... If there are other models out there that have dimensions I can try my hand at CADding them up too.