Smallshop

KNIFE MAKER

i did some gear work for a friends 1926 Rumley tractor...I traded a milling machine for it plus $500 his direction....The pic is not the exact machine but same condition and model...a FRAY Model C....geared head...upper table lower table...an amazing manual mill. cat 30 taper instead of r8...much stronger! and can take holder in and out without losing settings. Also horizontal mill capabilities.

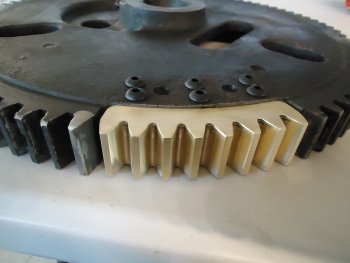

Here's the work I did for it...

We just timed the insert to the mating gear...tightened the six 1/4-20 screws....then we are removing it tomorrow to final ream and pin and lock-tighting of six screws....then in a week i move the "new" mill in....the milling machine is 1/4 mile from my house and my trade partner is moving it for me!

The tractor had been repaired twice...and broke again...I went with brass so that if it fails again we can repair again...I am certain that the repair I did was more accurate than brazing individual teeth back on...which was what was done the first two times.

Here's the work I did for it...

We just timed the insert to the mating gear...tightened the six 1/4-20 screws....then we are removing it tomorrow to final ream and pin and lock-tighting of six screws....then in a week i move the "new" mill in....the milling machine is 1/4 mile from my house and my trade partner is moving it for me!

The tractor had been repaired twice...and broke again...I went with brass so that if it fails again we can repair again...I am certain that the repair I did was more accurate than brazing individual teeth back on...which was what was done the first two times.