Kevin Zito

KNIFE MAKER

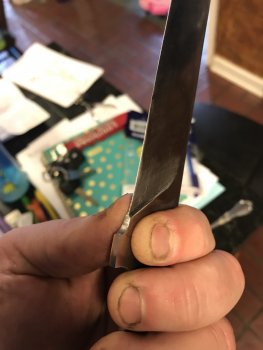

First thing’s first ... pahahah lol.

Now that we can move on lol. My dad and I debone a ton of pork and deer every year. So he put in a request for a boning knife. I’m gonna give this a whirl. I have a lot of grinding left to do. I want to focus more on fit and finish than ever before so I’m gonna keep it simple. This is my own design btw. Anyway critique away as usual. Thanks for looking.

Now that we can move on lol. My dad and I debone a ton of pork and deer every year. So he put in a request for a boning knife. I’m gonna give this a whirl. I have a lot of grinding left to do. I want to focus more on fit and finish than ever before so I’m gonna keep it simple. This is my own design btw. Anyway critique away as usual. Thanks for looking.