You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Nobody likes lockbacks?

- Thread starter Bob Warner

- Start date

marthinus

Well-Known Member

I like liner locks but would prefer a lock back for harder cutting. I have not attempted to make any (still trying to do fixed blades correctly on limited tools and HT is a pain for me at the momet) but this is my logic from using both. A well designed liner lock will with use wear faster then my lock back folders. When I apply a lot of force in cutting (which I do on the farm) a liner moves far over the tang, sometimes almost contact with the other scale. If you would try and unlock it then it will create excessive wear as one really have push hard and then it 'snaps' off the tang. How I have stopped this excessive wear by when finished cutting I push on the blade as I would cut and unlock the liner lock in the same motion and then stop applying pressure on the blade. Thereby the lock does not experience excessive wear (does this even make sense?)

The lock back design does not have this issue were it moves over the tang and experiences excessive wear. Lock back tends to have longer life span then a liner lock in my experience. I know the lock back has a stigma that one cannot open and close it one handed, but I can with the lock back design of Spyderco. The lock back also has a problem with it closing if ones grip is not right, well that happened to a liner lock as well and I have the cut to show. I gripped the knife wrong and while cutting unlocked it without my knowledge (my finger fat got in between the scale and the liner and unlocked). When I pulled the knife out of the rubber pipe (it was stuck a bit and I pulled it hard) it said halo here I am in your thumb.

Both have its pros and cons. For me the biggest concern is that a lock back has to be so well executed in order to be safe it can be time consuming for the maker. A liner experiences far more wear when used (in my uses) it has a shorter life span.

These days I prefer a well executed frame lock over a liner or lock back. It seems to have less wear issues then a liner (when the lock face is heat treated) and I have less chance of unlocking accidentally like I did with a liner. One can easily see if something is going wrong or starting to go wrong with the lock compared to a lock back so more 'visual safety'.

Please feel free to correct me if I am wrong! The more I learn the better.

The lock back design does not have this issue were it moves over the tang and experiences excessive wear. Lock back tends to have longer life span then a liner lock in my experience. I know the lock back has a stigma that one cannot open and close it one handed, but I can with the lock back design of Spyderco. The lock back also has a problem with it closing if ones grip is not right, well that happened to a liner lock as well and I have the cut to show. I gripped the knife wrong and while cutting unlocked it without my knowledge (my finger fat got in between the scale and the liner and unlocked). When I pulled the knife out of the rubber pipe (it was stuck a bit and I pulled it hard) it said halo here I am in your thumb.

Both have its pros and cons. For me the biggest concern is that a lock back has to be so well executed in order to be safe it can be time consuming for the maker. A liner experiences far more wear when used (in my uses) it has a shorter life span.

These days I prefer a well executed frame lock over a liner or lock back. It seems to have less wear issues then a liner (when the lock face is heat treated) and I have less chance of unlocking accidentally like I did with a liner. One can easily see if something is going wrong or starting to go wrong with the lock compared to a lock back so more 'visual safety'.

Please feel free to correct me if I am wrong! The more I learn the better.

I have never seen a lockback fail, so I'm curious where exactly they fail. Until earlier today when I stumbled upon a photo of one, I had never seen the detail of the locking mechanism on a lockback. At least on the one I saw, the mechanism looks fairly elegant. I'd love to hear an explanation of the failure modes. I'm not doubting them, I just can't get my head wrapped around where it occurs and what "catastrophic" result it would cause. Pictures of failed mechanisms or other disassembled views of mechanisms would definitely be appreciated.

marthinus

Well-Known Member

Not my picks but JC here you go

http://img4.imageshack.us/i/delica4lockup.jpg/

http://img39.imageshack.us/i/63271455.png/

The following are areas that I have heard of that can break on a lock back knife but they are unlikely if the knife is properly made:

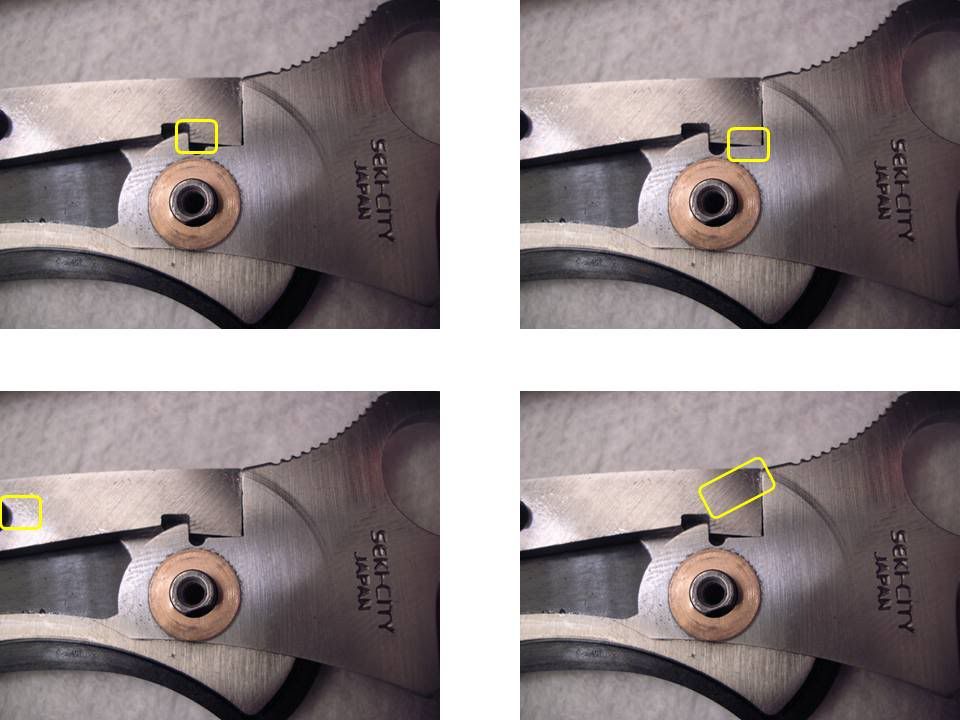

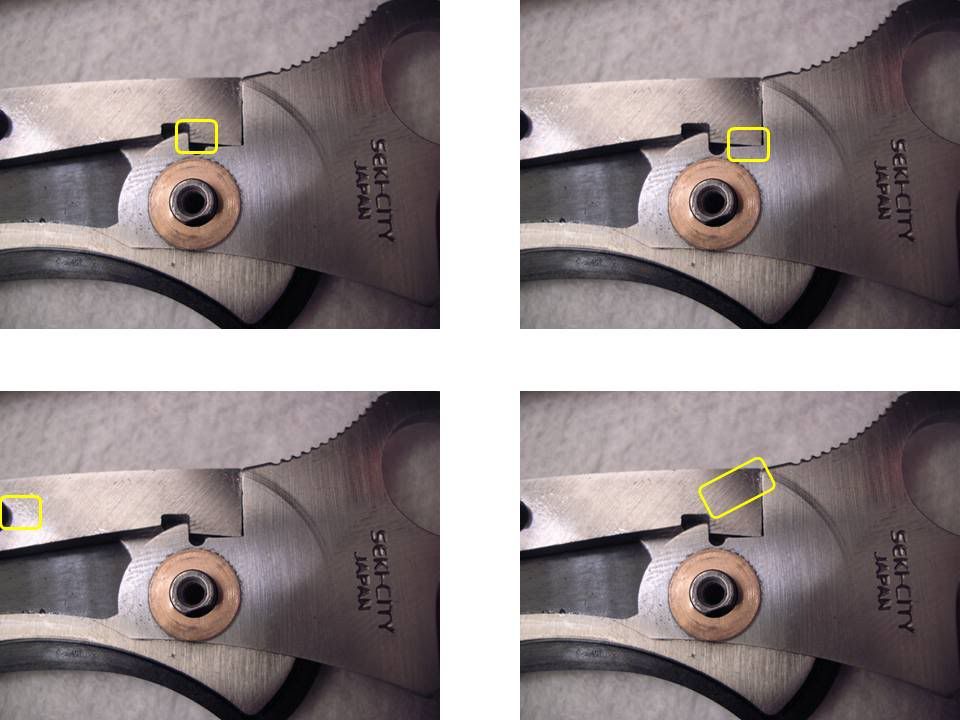

Pic1

The point of the lock can be worn or break off. The point of the notch on the right hand side can shear off.

Pic2

Right side of the notch can be clogged with lint, causing the lock not to lock up proparly

Pic3.

The pin and the spring can break if not tighten properly or is secure. Springs have broken, influencing lockup safety. The spacer wherein the spring goes can break if materials cannot take the force of the spring or the knife is assembled improperly.

Pic4

The lock can shear from corner to corner.

Now these are all things I have heard happen and some have been posted, others stated. 1,2 and 3 have happened for a fact. Number 4 I dont know. All and all any lock used in a proper manner will not have a catastrophic failure (ie the lock explodes and just becomes useless) if the knife is used properly, well designed and executed. Unless the stop pin or pivot pin shears out IMO.

Catastrophic result have been mentioned and documented. They are usually very bad cuts. This happened to me using a liner lock to cut hard material and in the process of pulling the knife out I disengaged the lock because I twisted my grip. Now I know there is a design flaw in this knife design, I like liner locks, they have their place, just not in a knife where harder cutting is applicable, Axis, Compression, Lock Back, Framelock are my preferred locks for harder cutting, less wear and tear on them and I feel I have more trust in them. Great for light chores, but I have learned. The cut was almost to the bone, bled like mad.

Others might have better input then me and if they do please correct me where I am wrong.

STR posted this years ago, but still interesting

The following is my opinion based on my own learning and growing from working on and rebuilding folders for a lot of years. Its long but worth the read. It is also first hand information from my own experience but as is true of everything you read on these forums take it with a grain of salt please and realize that it may or may not prove helpful to you. I hope it does but if not at least I tried..

If you are going to carry any folder that locks and especially a liner lock that you intend to carry for 'hard use' at least test the lock on occasion to be sure its doing its job securing the blade. Certainly do this after getting a new folder if you never do it again after that but periodic tests and examinations are highly recommened to maintenance them properly.

Contrary to popular belief you can test your folder lock without spine whacking it. Many people believe spine whacking does not harm a folder but believe me when you have seen as many knives as I do and broken down exposing the insides and taken to the level that you can separate out each individual part to examine it closely under magnification you can tell that spine whacking does indeed take its toll on a folders locking mechanism. Some folder lock designs suffer more from this than others. Based on my own observations it seems the Axis lock takes this test with the least obvious signs of it. Next would be the ball locks from Spyderco. All other lock types seem to show signs that this is anything but good for them though and usually related mostly to the lock mechanism and contact areas.

I've done Spine whacking in my own testing of knives for companies and taken brand new knives apart that were sent to me for field evaluation to report back on to the companies or the person that made it. On some of these after using them for normal use tests and cutting trials I have gone to the next level. I don't like doing this but feel on occasion it is worth knowing. Typically, I check them before whacking the spine to examine them, and then routinely have taken them apart again after whacking them and have seen evidence of the stress in the lockbars, the contacts of all surfaces and in the blade, and many times after repeated spine whacks in other parts as well including stop pins, and holes drilled out in the body of the folders for pivot barrels, lock bar pins, and stop pins.

I've seen oblong holes in FRN folders for the pivot and lockbars and this has proven to be true on other knives made with no steel or titanium liners but some man made material by itself and much easier over time with these liner less models than ones sporting steel reinforced liners. On almost every one of the thinner liner locking type folders I have whacked and examined you can see obvious wear spots on the titanium and stainless locks almost after the first whack.

These wear spots range from showing indenting into the locks that cause sticky hard to close lock mechanisms to shiny wear marks from friction by the harder blade being forced into the contacts under severe stress and pressure. I've also seen pins bowed in the middle on knives I've repaired and all I can figure is that great stress must have been exerted to make this happen. When I see your knife with a chunk of metal missing out of the lock in my shop I think to myself that it was something other than normal use that caused it 99.9% of the time and not because of faulty steel, or the company or person that made it doing something wrong. In all likelihood its from abuse I think in a lot of these cases, especially when I see fracture lines and that kind of thing. Whether or not the guy that mailed it to me did this or not is debateable but the point is it appears someone did at one time.

I have taken brand new 410 stainless frame locks Rockwell hardened to 45 RC and whacked them witnessing the lock go from barely engaging 1/3rd of the total thickness behind the blade to traveling all the way across the interface clear over to the non lock side to where the detent ball was touching the opposite side washer each and every time you opened the blade to use it whether it was snapped open hard or opened easy. This went from a good lock not even broke in yet to a worn out one in less than a day and all from spine whacking. No one can tell me whacking a folder on the spine is a good test. I beg to differ.

Now to the test method I prefer. I recommend standing with the knife like you see me holding an Emerson liner lock here in the link below. But I also recommend you make sure the lock is getting behind the blade at least to the full thickness of the liner itself before doing this test if you are carrying a thinner liner locking folder. However even on the thicker liner locks and frame locks doing it with barely any lock touching the blade to make contact can possibly shear or ding in part of the lock making it either unsightly or worse so the lock should be at least 50% behind the locks on these thicker lock styles if you ask me.

I've shown this test to people that have carried liner locks for many years thinking they walked on water (as I once did also) only to see their faces when they pushed up on the spine of the blade while securing it just as I'm doing here in the link below only to see the lock slide off the ramp interface and allow the blade to close on their very trusted knife and sometimes surprisingly with very little pressure at all. If the lock even moves at all in this test its not good. You can candy coat it all you want but its not good. A surprising number of knives tested this way fail surprisingly easy. If your lock moves a little but doesn't fail on you from this test, well you have to decide then if its one you want to just use knowing this, or send it in to who made it for evaluation or if its just time to retire it. The reason I say this is simply because of this thought. Just because it moved a little and didn't defeat with the pressure you could muster with this test doesn't mean that a stronger man, or more pressure from an extreme use of the tip won't cause the blade to close on your fingers. Only you can decide on the action you take at this point. And in fact if it moves or defeats you can decide then and there if you want to continue on or mail it for repairs at that point for the professional to look at.

You should do this with your lockback and axis lock folders, and all other 'locking' folders too on occasion as well as check the lock mechanisms for debris, pocket lint, damage and if they have springs check their condition as well unless you can't see them of course. Small spots of corrosion, or thinned weak looking areas on springs should be dealt with by a qualified repair pesron promptly when it comes to securing your fingers..Injury from a sharp blade closing on fingers can lead to serious incapacitation for a lengthy time, numbness or loss of other sensitivity in the fingers, tendon damage and lots of blood loss. Don't risk it out of blind faith.

Hold your knife so if the lock defeats you won't get cut just as I'm doing here in the link. You owe it to your fingers to know not suspect or blindly trust that the knife was made correctly. You don't have to @@@@ your wrist as I did here. I'm just doing that for my wife to get it in the shot easier. Hold it with both hands and using your strong hand with the blade resting on that index finger knuckle simply push up on the spine of your blade holding the body tight so its steady.

You can spine whack your knife if you just believe it causes no damage. But don't be surprised if when you find that it does in fact fail tests that the company doesn't cover the warranty due to the damage it caused to your folder on the inside. I'll leave your decision up to you when and if you cross that bridge.

STR

http://img4.imageshack.us/i/delica4lockup.jpg/

http://img39.imageshack.us/i/63271455.png/

The following are areas that I have heard of that can break on a lock back knife but they are unlikely if the knife is properly made:

Pic1

The point of the lock can be worn or break off. The point of the notch on the right hand side can shear off.

Pic2

Right side of the notch can be clogged with lint, causing the lock not to lock up proparly

Pic3.

The pin and the spring can break if not tighten properly or is secure. Springs have broken, influencing lockup safety. The spacer wherein the spring goes can break if materials cannot take the force of the spring or the knife is assembled improperly.

Pic4

The lock can shear from corner to corner.

Now these are all things I have heard happen and some have been posted, others stated. 1,2 and 3 have happened for a fact. Number 4 I dont know. All and all any lock used in a proper manner will not have a catastrophic failure (ie the lock explodes and just becomes useless) if the knife is used properly, well designed and executed. Unless the stop pin or pivot pin shears out IMO.

Catastrophic result have been mentioned and documented. They are usually very bad cuts. This happened to me using a liner lock to cut hard material and in the process of pulling the knife out I disengaged the lock because I twisted my grip. Now I know there is a design flaw in this knife design, I like liner locks, they have their place, just not in a knife where harder cutting is applicable, Axis, Compression, Lock Back, Framelock are my preferred locks for harder cutting, less wear and tear on them and I feel I have more trust in them. Great for light chores, but I have learned. The cut was almost to the bone, bled like mad.

Others might have better input then me and if they do please correct me where I am wrong.

STR posted this years ago, but still interesting

The following is my opinion based on my own learning and growing from working on and rebuilding folders for a lot of years. Its long but worth the read. It is also first hand information from my own experience but as is true of everything you read on these forums take it with a grain of salt please and realize that it may or may not prove helpful to you. I hope it does but if not at least I tried..

If you are going to carry any folder that locks and especially a liner lock that you intend to carry for 'hard use' at least test the lock on occasion to be sure its doing its job securing the blade. Certainly do this after getting a new folder if you never do it again after that but periodic tests and examinations are highly recommened to maintenance them properly.

Contrary to popular belief you can test your folder lock without spine whacking it. Many people believe spine whacking does not harm a folder but believe me when you have seen as many knives as I do and broken down exposing the insides and taken to the level that you can separate out each individual part to examine it closely under magnification you can tell that spine whacking does indeed take its toll on a folders locking mechanism. Some folder lock designs suffer more from this than others. Based on my own observations it seems the Axis lock takes this test with the least obvious signs of it. Next would be the ball locks from Spyderco. All other lock types seem to show signs that this is anything but good for them though and usually related mostly to the lock mechanism and contact areas.

I've done Spine whacking in my own testing of knives for companies and taken brand new knives apart that were sent to me for field evaluation to report back on to the companies or the person that made it. On some of these after using them for normal use tests and cutting trials I have gone to the next level. I don't like doing this but feel on occasion it is worth knowing. Typically, I check them before whacking the spine to examine them, and then routinely have taken them apart again after whacking them and have seen evidence of the stress in the lockbars, the contacts of all surfaces and in the blade, and many times after repeated spine whacks in other parts as well including stop pins, and holes drilled out in the body of the folders for pivot barrels, lock bar pins, and stop pins.

I've seen oblong holes in FRN folders for the pivot and lockbars and this has proven to be true on other knives made with no steel or titanium liners but some man made material by itself and much easier over time with these liner less models than ones sporting steel reinforced liners. On almost every one of the thinner liner locking type folders I have whacked and examined you can see obvious wear spots on the titanium and stainless locks almost after the first whack.

These wear spots range from showing indenting into the locks that cause sticky hard to close lock mechanisms to shiny wear marks from friction by the harder blade being forced into the contacts under severe stress and pressure. I've also seen pins bowed in the middle on knives I've repaired and all I can figure is that great stress must have been exerted to make this happen. When I see your knife with a chunk of metal missing out of the lock in my shop I think to myself that it was something other than normal use that caused it 99.9% of the time and not because of faulty steel, or the company or person that made it doing something wrong. In all likelihood its from abuse I think in a lot of these cases, especially when I see fracture lines and that kind of thing. Whether or not the guy that mailed it to me did this or not is debateable but the point is it appears someone did at one time.

I have taken brand new 410 stainless frame locks Rockwell hardened to 45 RC and whacked them witnessing the lock go from barely engaging 1/3rd of the total thickness behind the blade to traveling all the way across the interface clear over to the non lock side to where the detent ball was touching the opposite side washer each and every time you opened the blade to use it whether it was snapped open hard or opened easy. This went from a good lock not even broke in yet to a worn out one in less than a day and all from spine whacking. No one can tell me whacking a folder on the spine is a good test. I beg to differ.

Now to the test method I prefer. I recommend standing with the knife like you see me holding an Emerson liner lock here in the link below. But I also recommend you make sure the lock is getting behind the blade at least to the full thickness of the liner itself before doing this test if you are carrying a thinner liner locking folder. However even on the thicker liner locks and frame locks doing it with barely any lock touching the blade to make contact can possibly shear or ding in part of the lock making it either unsightly or worse so the lock should be at least 50% behind the locks on these thicker lock styles if you ask me.

I've shown this test to people that have carried liner locks for many years thinking they walked on water (as I once did also) only to see their faces when they pushed up on the spine of the blade while securing it just as I'm doing here in the link below only to see the lock slide off the ramp interface and allow the blade to close on their very trusted knife and sometimes surprisingly with very little pressure at all. If the lock even moves at all in this test its not good. You can candy coat it all you want but its not good. A surprising number of knives tested this way fail surprisingly easy. If your lock moves a little but doesn't fail on you from this test, well you have to decide then if its one you want to just use knowing this, or send it in to who made it for evaluation or if its just time to retire it. The reason I say this is simply because of this thought. Just because it moved a little and didn't defeat with the pressure you could muster with this test doesn't mean that a stronger man, or more pressure from an extreme use of the tip won't cause the blade to close on your fingers. Only you can decide on the action you take at this point. And in fact if it moves or defeats you can decide then and there if you want to continue on or mail it for repairs at that point for the professional to look at.

You should do this with your lockback and axis lock folders, and all other 'locking' folders too on occasion as well as check the lock mechanisms for debris, pocket lint, damage and if they have springs check their condition as well unless you can't see them of course. Small spots of corrosion, or thinned weak looking areas on springs should be dealt with by a qualified repair pesron promptly when it comes to securing your fingers..Injury from a sharp blade closing on fingers can lead to serious incapacitation for a lengthy time, numbness or loss of other sensitivity in the fingers, tendon damage and lots of blood loss. Don't risk it out of blind faith.

Hold your knife so if the lock defeats you won't get cut just as I'm doing here in the link. You owe it to your fingers to know not suspect or blindly trust that the knife was made correctly. You don't have to @@@@ your wrist as I did here. I'm just doing that for my wife to get it in the shot easier. Hold it with both hands and using your strong hand with the blade resting on that index finger knuckle simply push up on the spine of your blade holding the body tight so its steady.

You can spine whack your knife if you just believe it causes no damage. But don't be surprised if when you find that it does in fact fail tests that the company doesn't cover the warranty due to the damage it caused to your folder on the inside. I'll leave your decision up to you when and if you cross that bridge.

STR

Last edited:

Thanks for the explanation. I could see how, in the example you've posted pictures of above, there would be some notch sensitivity with that design. As is typical of just about any stressed application, all corners should have the largest radius possible to minimize any potential for stress concentrations. Personally, if I were designing a lockback, I'd avoid that notch altogether, like on the picture that I linked to.