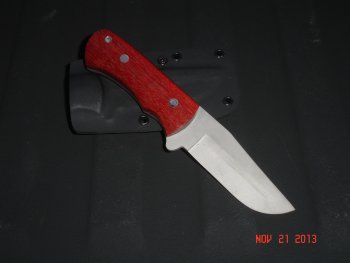

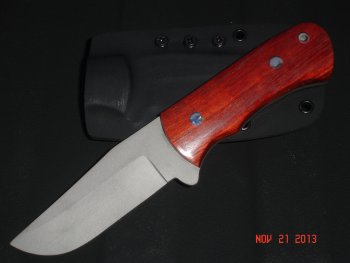

I have had good results using Padauk for handle material. It took me a little while to learn how to finish this wood the best way for knife scales. I had mine stabilized before use. Here is what I did. After finishing down to 600 grit, I used a CA (Super Glue) for a sealer and then GENTLY buffed for a high gloss shine. If you buff to aggressively, the CA will "melt" and you'll have a mess and have to start over with finishing. If you want something more subdued, after sanding down to whatever grit you want to use, gently buff and you will end up with a nice matte to semi gloss finish, but you'll still have that open grain structure. Experiment a little before you put it on a knife with what type of finish you want.

Things I found out while working Padauk.........

The open grain structure will hold dirt, saw dust and buffing compound etcetera if you use too much pressure while buffing and give the wood a "dirty" appearance, a gentle touch goes a long way. Even though padauk is not that hard of a wood, it seemed to dull my cutting tools quickly.

Padauk also changes color with exposure to light and with age. This is the main reason why I had mine stabilized before use. So far, after stabilization, I have not noticed any discoloration or darkening yet. And with the padauk I had, when freshly cut, the saw dust is bright orange, like traffic cone orange! I got a kick out of that. If you can put up with it's quirks, padauk, will make a very nice handle material.

.

View attachment 49923 View attachment 49924View attachment 49925View attachment 49926