I'm not sure which alloy you're using, but for AEB-L the preheat is 1725°F, then clamped in quench plates. I leave them in until oven reaches final temp. Hoss (Larrin's Dad) gave a good write up on his preferred method where he says to remove from oven during ramp up. Temper twice,

first temper for 1 hour at 350F, 2nd temper for 2 hours – choose temperature based on Rc test prior to temper. The reason for 2nd temper is to covert even more RA.

Larrin has a good white paper on AEB-L here:

https://knifesteelnerds.com/2019/03/04/all-about-aeb-l/

Here's a short excerpt from the link:

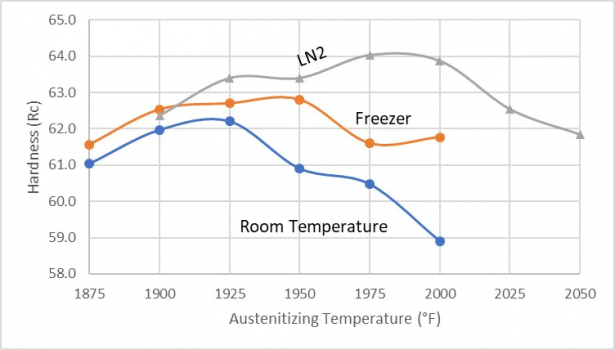

For each temperature I held for 15 minutes prior to a plate quench, followed by either liquid nitrogen for 30-60 minutes, my household freezer for 30-60 minutes, or no cold treatment. As expected, the liquid nitrogen treatment cryogenic treatment led to the highest hardness, followed by the freezer, then room temperature. {snip}1925°F with room temperature, 1950°F with the freezer, and 1975°F with liquid nitrogen. The peak hardness was increased from 62.2 Rc with room temperature to 62.8 Rc with the freezer, to 64 Rc with liquid nitrogen. Higher austenitizing temperature means more carbon in solution for higher hardness.

View attachment 80051