D. Crawford

Well-Known Member

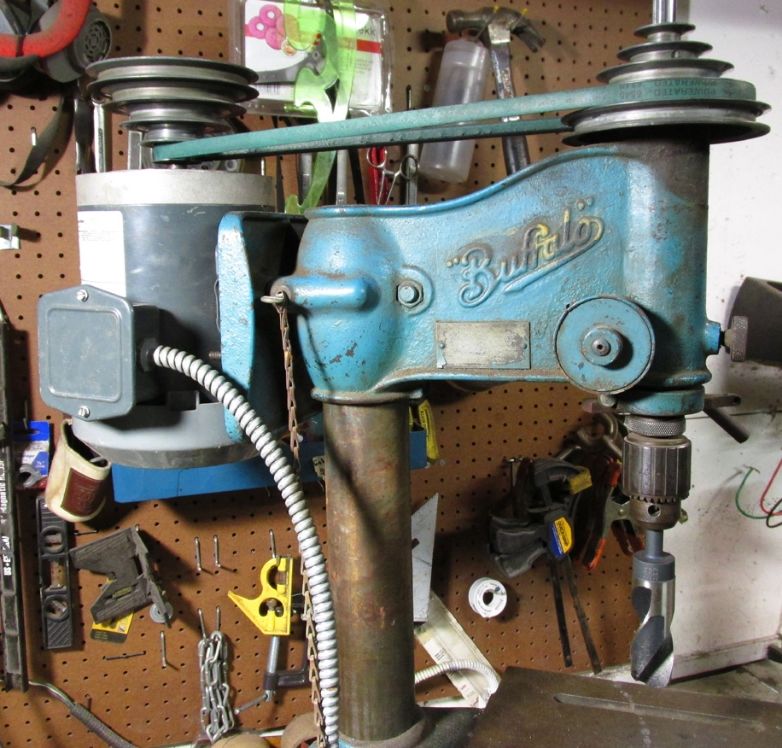

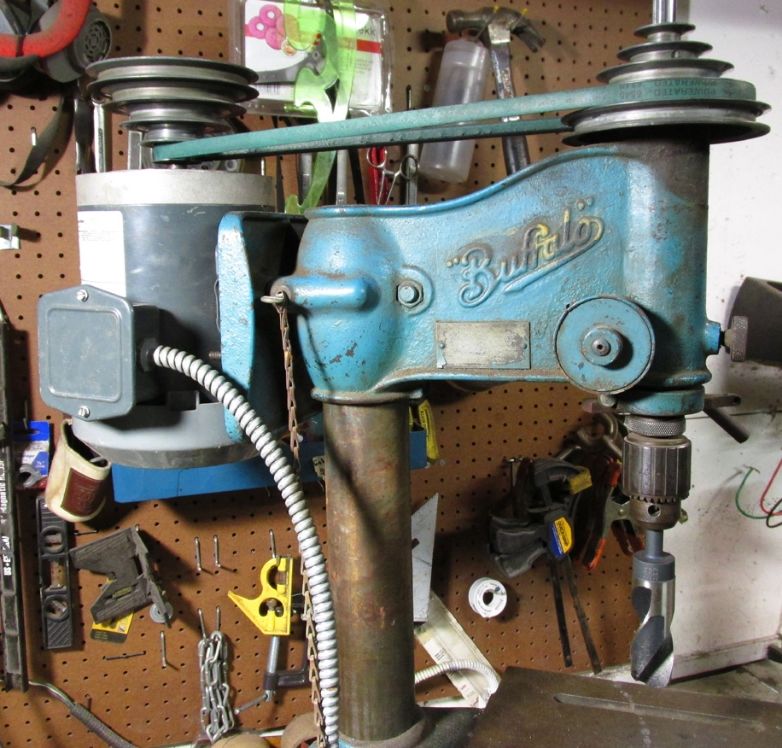

I'm in the process of building a hydraulic press and needed to drill some 1.250" holes in very thick stock. Neither of my two benchtop drills were up to the task. They were too fast & didn't have nearly enough torque. After reading several threads at some of the machinists forums I came up with the following to get the holes drilled... and the changes only took about 20 minutes.

This old Buffalo is the bigger, heavier of my two drill presses and also has a 1/2" chuck for large bits. I removed the old motor (1/3 hp I think) and the motor mounting plate.

I then bolted on a spare 1 hp motor (3 Phase) onto the mounting plate and re-installed it onto the drill press.

The pulley was drilled from 1/2" to 5/8" to fit the bigger motor shaft.

Lastly, I wired the new motor into my grinder's VFD. Now I have a variable speed drill press capable of drilling 1"+ holes in thick steel. A new belt insures that the extra power gets transferred to the work piece without slipping.

Hope this helps someone needing to drill larger diameter holes.

This old Buffalo is the bigger, heavier of my two drill presses and also has a 1/2" chuck for large bits. I removed the old motor (1/3 hp I think) and the motor mounting plate.

I then bolted on a spare 1 hp motor (3 Phase) onto the mounting plate and re-installed it onto the drill press.

The pulley was drilled from 1/2" to 5/8" to fit the bigger motor shaft.

Lastly, I wired the new motor into my grinder's VFD. Now I have a variable speed drill press capable of drilling 1"+ holes in thick steel. A new belt insures that the extra power gets transferred to the work piece without slipping.

Hope this helps someone needing to drill larger diameter holes.

Last edited: