Ty Adams

KNIFE MAKER

It looks like like I'm finally going to have time for knife making. With the new shop having more power than Thors hammer I want to add some tools that will help make life easier and speed my process. So after not taking orders for some time I have let some very patient people know that my books are open for a short time.

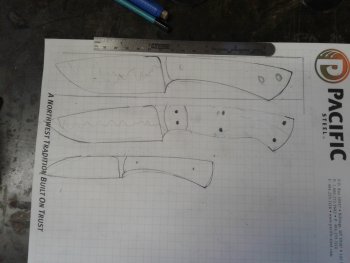

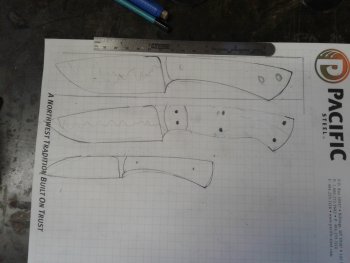

The number one thing that is almost always asked by potential customers here in Montana is why are my knives so small. You know bigger is always better when field dressing wild game! So this morning I designed a couple of knives that are larger than what I personal like. I'm looking for some input on what you guys think of the new designs. Sorry for the blades running into the letters the original length of the blades where out of proportion to handles. The bottom knife is a utility blade for cutting cord, and zip ties while setting trail cams and tree stands.

The number one thing that is almost always asked by potential customers here in Montana is why are my knives so small. You know bigger is always better when field dressing wild game! So this morning I designed a couple of knives that are larger than what I personal like. I'm looking for some input on what you guys think of the new designs. Sorry for the blades running into the letters the original length of the blades where out of proportion to handles. The bottom knife is a utility blade for cutting cord, and zip ties while setting trail cams and tree stands.