Are you talking about the image being the initial "stack"? If so, there's way more there to go wrong, then I would take a stab at trying to do.

Typically, the fewer the layers, and the more of them that run in the same orientation, the less likely you are to have issues. You're biggest potential problem with that being an initial "stack", is the middle stack/square.....there's little to no way for any debris, flux, etc. to get in or out. Very high probability of inclusions and/or cold shuts. You also have to realize/understand, that squaring dies are best used for ONLY the initial welding.....as the squaring dies themselves become a mechanism that traps flux, debris, etc. IN a billet. Typically, after the in initial weld, I will go to my air hammer, with drawing dies....which is a much faster method of drawing out then my press. The press comes into play at the end, and is used with flat dies and stop blocks to finish truing up the billet.

Typically what I would do is to weld ONE of those squares, or more to the way I do it...... I would make each of those stacks/squares, it's own billet..... weld them all up as individuals, draw them to the same size, then grind all four sides, cut, and make as many 4-ways as you choose. Then you're only actually welding up 4 bars, cutting your chances of failures dramatically, versus trying to weld us 60+ layers that are in different orientations...then draw it out as long as possible down to whatever sized square you wish.

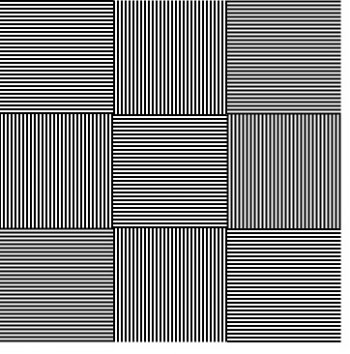

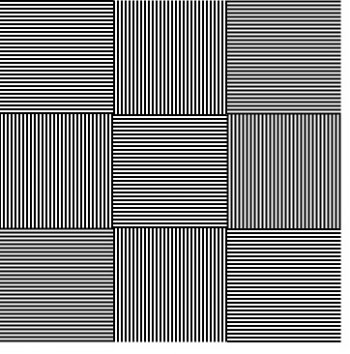

Personally, I usually go with 1" or 1 1/4" square, grind off all four sides, then cut it into 4 equal length pieces. Sand and etch the ends of each piece, and then orient them as desired into a 4-way..... sorta of like 4 squares making up the lower left corner of your image. Weld those, then draw and size...... for either a finished piece, or into another 4-way, or even 9-way. I rarely go more than a 9-way of pre-welded bars, simply because it more often then not, ends in a failure. On occasions I have been know to do a 16-way billet....but that is reserved for "loaves".....that I take slices off to make something smaller, such as folder blades or scales.

IMO, the worst self handicapping a person can try to do when creating Mosaics, are to try to do it all at once (like trying to weld the entire image/stack above).....which generally ends in some type of failure. Rather, think of creating Mosaics as "One more manipulation"..... meaning one more 4-way, or one more 9-way.

Hope that's helpful!