The steel came from Kelly Cupples. I didn't normalize, anneal, or forge the blade. I stuck it into the oven and programmed it to go to 1480. I let it soak for a couple minutes and then pulled it out and quenched it in canola. You are the expert Mr. Cashen, if you say it is overheated, it is overheated, I just don't see how I could have done that unless 1480 is too hot. Thanks again.

Alden, I really appreciate your confidence in me, but rather than an expert, just think of me as a person who has made a lot more mistakes than most. But along with those mistakes I also have a built-in, obsessive, need to verify and question all results or explanations. This is why I encourage people to never take my word for gospel but always question things and verify for themselves. The greatest compliment I can receive is "Kevin, I thought you were full of it, so I tested it and found out you were right" in that way I have done people a greater service than being just another internet expert; the internet already has a surplus of "experts."

Having said all that, I would strongly suggest that you look to your heating equipment, and time. One of the great misunderstanding about grain size on simple steels is that it is somehow some sort of permanent or persistent problem, when it is actually one of the quickest and easiest issues to fix. On every heat through non-magnetic (Ac1 for those who will want precise terms) the steel will recrystallize, this gives you the opportunity to entirely reset that grain size in a single heat. This can be affected, somewhat, by the previous grain size

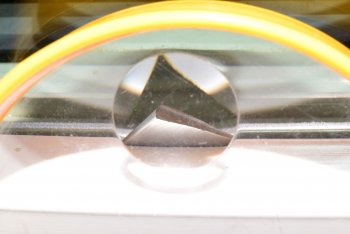

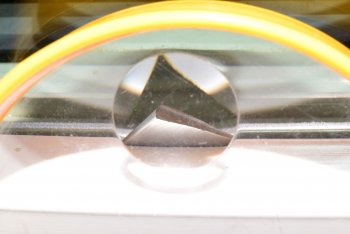

if it was absolutely, out of control, huge. The new grain network will form within the boundaries of the previous grain boundaries. So, an ASTM grain size of 1 or 2 (huge) could result in a size 6 on reheat, requiring another cycle to get it back to 8 or 9, but this is an extreme situation to say the least. By far the most likely explanation of a grain condition such as this is the result of the last heat on the steel.

1480°F is not too high for 1080, but it is on the high side of the necessary range, and could allow the grain to grow a little if held for too long. Try 1425°F to 1450°F, keeping in mind that soak times are not really necessary for 10XX series steels, and the closer you get to 1500°F, the more likely you will get a grain size bump by holding longer than necessary.

Another motto that I have tried to live by is that any smart person will learn from their own mistakes, but a wise person learns from other peoples mistakes, this is the only thing that will allow you to learn more than one lifetime worth of lessons. I have the benefit of having bladesmiths, and other industries, from around the world coming to me with their problems, and so I have seen a lot of odd things. I did have one situation with a steel that was sent to me for testing, that was fairly unique in the gran size discussion. It was an odd batch of 1075, in another country, that could not have its grain size refined. My lab work showed that there was some sort of contamination or segregation at the grain boundaries that left a permanent framework of ASTM size 6 to 7 boundaries that all efforts to cycle down only created finer grains within this network but the steel when broken, would fracture at the flawed larger network boundaries. This gave the unchangeable appearance of large fractured grains, but any efforts to refine the size could only be detected with special metallography to reveal the sub-grains. I only relay this information to stress how rare something like this would be and that 99% of the time the answer is to check and calibrate your heat source.

Edited to add- I have found that the most important heat equipment to check and calibrate is one that is brand new. There are too many unknown variables in an oven that has just arrived at your shop and has not been made "part of the family" yet. I have several brands of ovens and controllers in my shop and every one of them needed calibration and careful setup for my way of doing things. The only ones that I trust are the ones that have been maintained by me for years, and I trust them because I double check them on every firing. Come to my shop in a heat treat day and you will see cords and wires everywhere as every heat source will have three different pyrometers double checking each other.