Navin_R_Johnson

Active Member

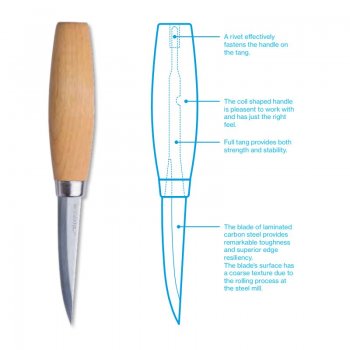

I have a few friends and family members that like to wood carve and I'm just spooling up on how to go about making a few knives for some of them. When I looked at the popular, among wood carvers, Mora carving knives I noticed the handle fastener on the rear end looks to be slid over the tang and peened on? Is that correct? (image attached)

Has anyone used this method that could give a bit of detail on process? Prep to the rivet and tang before peening?

Has anyone used this method that could give a bit of detail on process? Prep to the rivet and tang before peening?