C Craft

Well-Known Member

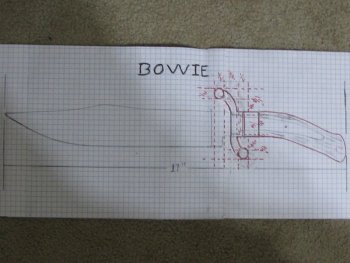

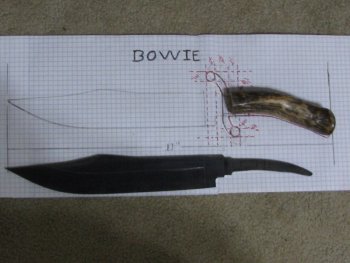

When you are drawing up a knife. Have you ever seen something wrong, something that bugs you but, you can't quite figure out what that something is!! It is that little voice in the back of your head saying, "that is not right"! I have had a drawing of a Bowie I am working on and try as hard as I might there was something about it, I just did not like!

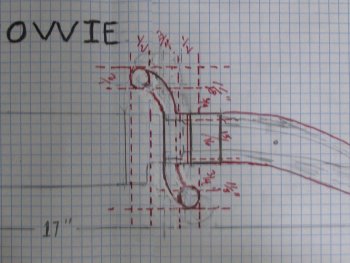

So today I had a little time to sit and stare at the drawing and it hit me. I did not like the guard for the knife. As many times as I looked at that drawing I couldn't figure it out what it was I didn't like!! Today I was determined to find that problem or scrap the whole project.

This will be the first time I ever drew a knife out to proportion and designed with repeatable measurements!! I think it was John Wilson told me that he does a proportionate drawing for every knife he builds and matches the pieces/parts to the drawing.

Like I said I may do a drawing but not a proportionate drawing. Sometimes that works for me and sometimes it doesn't!

When it doesn't it usually creates a mess that has to be worked out on the fly. Sometimes that can be a real PETA!

I think I am gonna like the idea of doing a proportionate drawing! Drawing a knife on graph paper really does work!! Thanks for the advise John!!

So today I had a little time to sit and stare at the drawing and it hit me. I did not like the guard for the knife. As many times as I looked at that drawing I couldn't figure it out what it was I didn't like!! Today I was determined to find that problem or scrap the whole project.

This will be the first time I ever drew a knife out to proportion and designed with repeatable measurements!! I think it was John Wilson told me that he does a proportionate drawing for every knife he builds and matches the pieces/parts to the drawing.

Like I said I may do a drawing but not a proportionate drawing. Sometimes that works for me and sometimes it doesn't!

When it doesn't it usually creates a mess that has to be worked out on the fly. Sometimes that can be a real PETA!

I think I am gonna like the idea of doing a proportionate drawing! Drawing a knife on graph paper really does work!! Thanks for the advise John!!

Last edited: