You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What's going on in your shop?

- Thread starter Justin Presson

- Start date

Edwardshandmadeknives

Well-Known Member

Winter time here in Minnesota. I don’t have anything going on to post.I’m sad to see this forum slipping away.

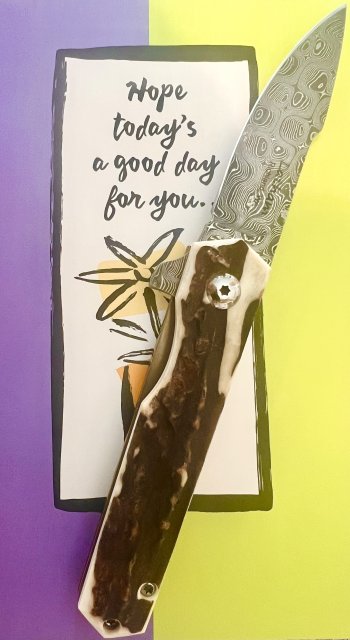

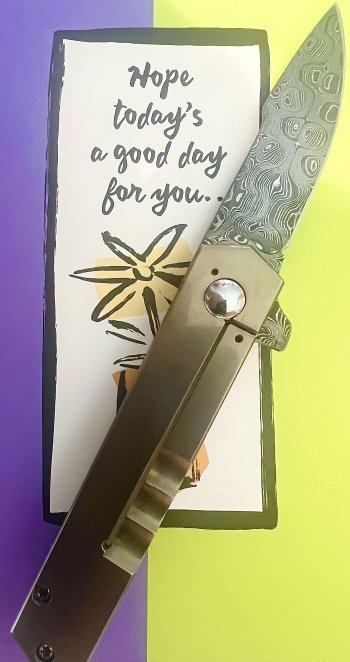

Here is a new flipper from my shop.

Got a double clamp plate quench set up for my 1x4x30 aluminum quench plates.

Got a Dry Ice/DNA slurry tray made up for a sub zero treatment of blades that don't fit into my LN2 dewar.

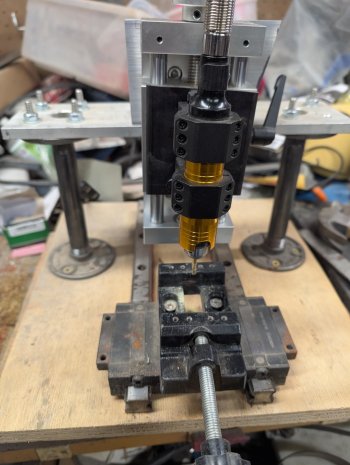

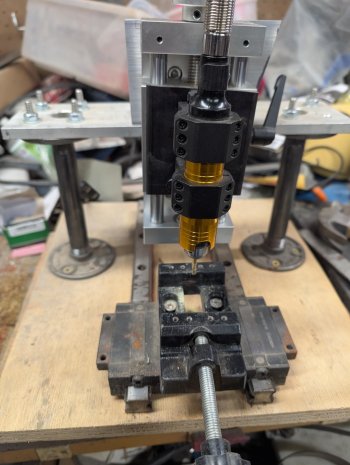

Upgraded Dremel Mill to be much more rigid with a new linear slide table:

Nice and clean cuts 1/16" and 1/8" wide!

Magnacut FBBO smaller size, yellow pins, liners and lanyard tubing, OD green/Burlap handle scales. Yellow Kryptek sheaths for pocket carry and horizontal carry

Had some 1/16" x 5.3" x 1" cutoffs, so I tried making a super thin/slicey scapel! Gotta do more handle shaping, sheath and sharpen to see how it holds up!

Got a Dry Ice/DNA slurry tray made up for a sub zero treatment of blades that don't fit into my LN2 dewar.

Upgraded Dremel Mill to be much more rigid with a new linear slide table:

Nice and clean cuts 1/16" and 1/8" wide!

Magnacut FBBO smaller size, yellow pins, liners and lanyard tubing, OD green/Burlap handle scales. Yellow Kryptek sheaths for pocket carry and horizontal carry

Had some 1/16" x 5.3" x 1" cutoffs, so I tried making a super thin/slicey scapel! Gotta do more handle shaping, sheath and sharpen to see how it holds up!