dswait

Well-Known Member

This knife I completed last December, but took detail pictures of the process from start to finish (leaving out the sheath and sharpening). This is a stock removal process and I decided to make a simple knife for a gift giveaway at work. There's many ways to make a knife and this is just showing you one way that I've learned to do it with my ever evolving knife making process. I think it came out okay and the coworker that received it absolutely loved it. It's not the best knife, but I feel the next knife I do will be even better.

Before starting, the first thing you need to consider is safety. Since most of the time will be spent behind the grinder, it is important to have safety goggles, a good respirator, and safety gloves. These should be worn at all times while working behind the bench grinder or belt sander. It is also a good idea to wear these items while hand sanding too, as you don't want to breath in dust particles or get them in your eyes.

The first step of the process is to draw out on paper the design of the knife you want to make. I decided to go with a very simplistic design, since I decided on doing this last minute. If I recall, I think my design consisted of a 3" blade, 1/2" ricasso, and a 4" handle. Ricasso is the flat center area of the knife between the blade and handle, every good knife design should have one.

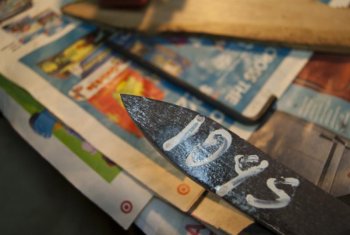

For this knife, I used 1095 bar stock .187" thick by 1" wide. I used it because it was what I had on hand at the time. I like using 1084 or 1095, and if I had the choice, would have gone with 1084 and something a little more thin. After cutting the bar stock to the length that I need using a cut off wheel, I took the paper template and a black marker and traced it onto the bar stock. The area marked in black is what needs to be removed.

Now we take the bar stock to the bench grinder and start removing the area we marked in black. A coarse grit stone will make short work of the metal. You don't need to take it all the way, you can leave a little to remove later on the belt sander.

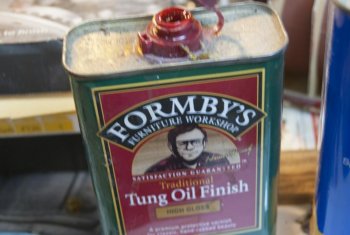

As you work the piece, from time to time you will need to dunk it in water to cool it. I like to use a pitcher full of glass cleaner. Reason is because I find metal doesn't form rust as quickly using glass cleaner, but you are welcome to use water.

After a few minutes of grinding, you should start to see it take some shape.

After you get the tip close to where you want it, move onto profiling the handle.

Before starting, the first thing you need to consider is safety. Since most of the time will be spent behind the grinder, it is important to have safety goggles, a good respirator, and safety gloves. These should be worn at all times while working behind the bench grinder or belt sander. It is also a good idea to wear these items while hand sanding too, as you don't want to breath in dust particles or get them in your eyes.

The first step of the process is to draw out on paper the design of the knife you want to make. I decided to go with a very simplistic design, since I decided on doing this last minute. If I recall, I think my design consisted of a 3" blade, 1/2" ricasso, and a 4" handle. Ricasso is the flat center area of the knife between the blade and handle, every good knife design should have one.

For this knife, I used 1095 bar stock .187" thick by 1" wide. I used it because it was what I had on hand at the time. I like using 1084 or 1095, and if I had the choice, would have gone with 1084 and something a little more thin. After cutting the bar stock to the length that I need using a cut off wheel, I took the paper template and a black marker and traced it onto the bar stock. The area marked in black is what needs to be removed.

Now we take the bar stock to the bench grinder and start removing the area we marked in black. A coarse grit stone will make short work of the metal. You don't need to take it all the way, you can leave a little to remove later on the belt sander.

As you work the piece, from time to time you will need to dunk it in water to cool it. I like to use a pitcher full of glass cleaner. Reason is because I find metal doesn't form rust as quickly using glass cleaner, but you are welcome to use water.

After a few minutes of grinding, you should start to see it take some shape.

After you get the tip close to where you want it, move onto profiling the handle.

Last edited: