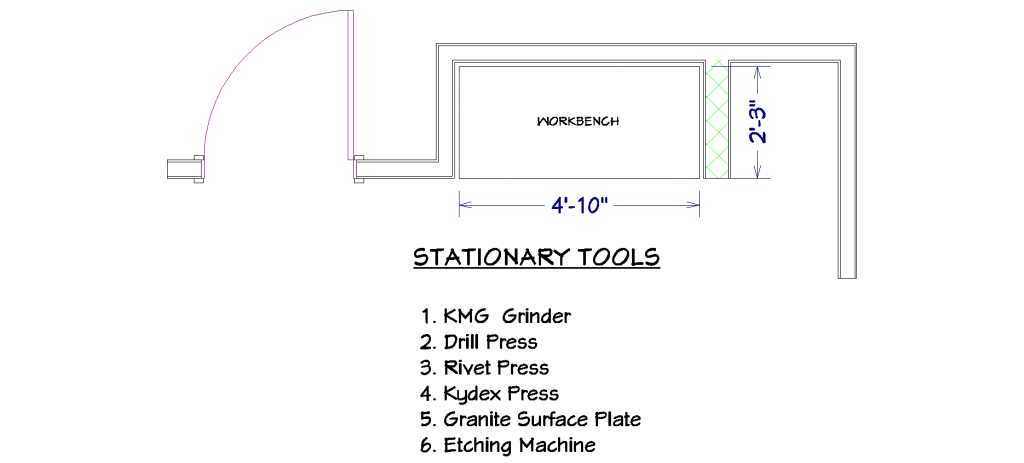

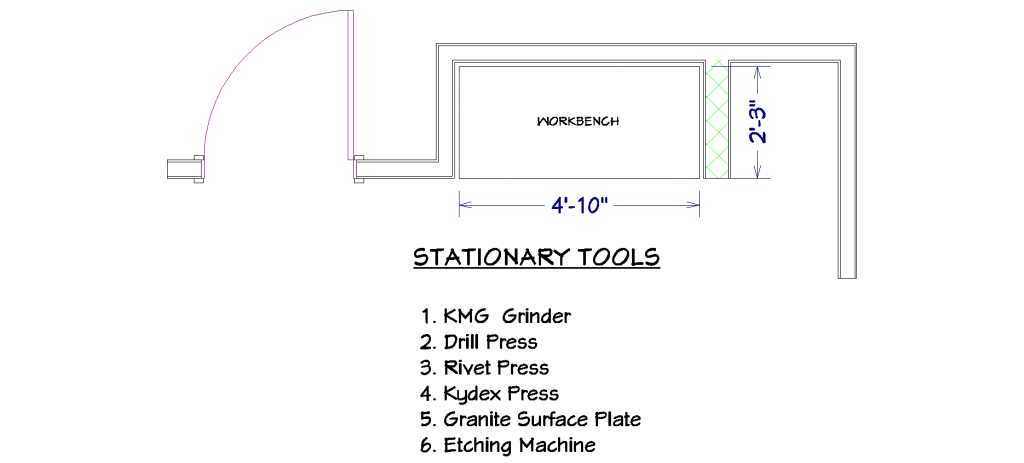

Is that drawing what you've got as far as space? You're going to be really crowded! Even with another 5' bench, I'm afraid you'll be crowded with all that. Is the drill press a bench-model or floor? I'd say the 4'10" bench would be taken up almost completely with just the grinder. You have to have room beside the grinder to set blanks, jigs, cup of coffee, etc. Might be enough for a bench-top drill press too, but seems crowded.

I have an 8' bench and a 5' bench and I am constantly shuffling things around to a shelf below bench. The big one is for knife making, the smaller for sheath making. My drill press, mill, disc sander, lathe, etc. are all floor models. I also have a bandsaw and now a HT oven on yet another bench. I'm sure there are a lot of guys with less space, but if you're really crowded and constantly having to move stuff, it sure sucks the fun out of it.

This going into a garage? Might have to make the wife park outside.:1: