You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Polishing knife blanks

- Thread starter martin

- Start date

I have just sent you a picture of 2 sample knife blanks. Yes, they are large. Yes, they are thin - approximately .070 at the spine for the longer blade. the shorter blade should have been ground to approximately .060. The blank is not ground to edge. A thickness of .01 should have been left at edge by the grinder. It might be easier if I send you a sample or 2 of this material to see how it responds. thank you.photos would help

Von Gruff

KNIFE MAKER

I have just sent you a picture of 2 sample knife blanks. Yes, they are large. Yes, they are thin - approximately .070 at the spine for the longer blade. the shorter blade should have been ground to approximately .060. The blank is not ground to edge. A thickness of .01 should have been left at edge by the grinder. It might be easier if I send you a sample or 2 of this material to see how it responds. thank you.

Not to me thanks Martin but I thought that a picture would give possible polishers a better idea of what you wanted. I had understood when you said a knife blank that it would be a knife shaped piece and then you added that they were a rectangle so it was more a case of having that cleared up that I made the sugestion.

John Wilson

Well-Known Member

I was also hoping, as Von Gruff was, that a picture would clarify what you were asking for. Yes, you did say that these were rectangle- but that did not make sense to me. Now that you have shown that they are indeed heat treated sheet steel, I am left scratching my head.

May I ask why someone would begin with an already hardened piece of steel? Many of us grind our blades after they are hardened, however the hole drilling and profile shaping has already been done while in the annealed state. I am not quite sure what I could possibly do with a piece of hardened steel- especially one that is already polished for some reason.

Please don't take this as any sort of personal criticism. I'm sure you have your reasons. If you care to explain, I'd love to hear it. If you are simply asking for someone to polish these without asking questions then I wish you good luck, but it is not something I'd be interested in.

May I ask why someone would begin with an already hardened piece of steel? Many of us grind our blades after they are hardened, however the hole drilling and profile shaping has already been done while in the annealed state. I am not quite sure what I could possibly do with a piece of hardened steel- especially one that is already polished for some reason.

Please don't take this as any sort of personal criticism. I'm sure you have your reasons. If you care to explain, I'd love to hear it. If you are simply asking for someone to polish these without asking questions then I wish you good luck, but it is not something I'd be interested in.

John Wilson

Well-Known Member

After re-reading your post, perhaps I am off base. Now I am thinking that these are indeed finished blades and you simply want them polished. Gliden asked that question but you didn't respond, which is why I think we were all confused as to what you are after.

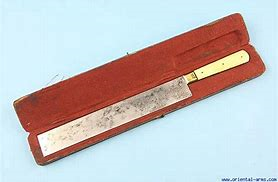

Upon closer inspection I see that the bevels are indeed ground. I had mistaken the angles for shadows. So apparently these are industrial /commercial blades? Not that it matters the least bit, just thinking out loud.

Upon closer inspection I see that the bevels are indeed ground. I had mistaken the angles for shadows. So apparently these are industrial /commercial blades? Not that it matters the least bit, just thinking out loud.

I was also hoping, as Von Gruff was, that a picture would clarify what you were asking for. Yes, you did say that these were rectangle- but that did not make sense to me. Now that you have shown that they are indeed heat treated sheet steel, I am left scratching my head.

May I ask why someone would begin with an already hardened piece of steel? Many of us grind our blades after they are hardened, however the hole drilling and profile shaping has already been done while in the annealed state. I am not quite sure what I could possibly do with a piece of hardened steel- especially one that is already polished for some reason.

Please don't take this as any sort of personal criticism. I'm sure you have your reasons. If you care to explain, I'd love to hear it. If you are simply asking for someone to polish these without asking questions then I wish you good luck, but it is not something I'd be interested in.

you are quite right. these ARE the profiled shape. This is a unique shaped knife. And yes THIS IS the finished shape . Almost 2.25 wide 16-19 inch long blade. 1/2 tang of about 5 inch long. The use of this blade is exclusively for kosher slaughter. I have also provided these to the Muslem community. Due to the thinness of the blade I have always H.T. first. Open to suggestions. All of the grinding is done on a paper knife grinding machine. Emulsion cooling fluid,magnetic chuck ,keeps the prescion. There are the swirl marks left on the blade. These swirls is what I need removed , and then polished. The cutting of the pin placement holes are usually done before H.T. I have learned that placing the holes commits to the placement of the handle. using CARBIDE TIPPED glass drill bits , allows me to drill these holes without difficulty.

Thank you all. When I started , it was ROAST BEEF SLICERS that were cut down to 5" blades. Cutting hard steel is not a problem. The half tang that is eventually removed is NOT discarded. I also have a bug in my head, to keep the blade hanging straight in the H.T. oven . Hence the removal of the bottom of the half tang is done later. As to your Q. It is not to benefit the tang per-se that I work this way. Thank you again

Yes that is a pic. of the type of knife that I make. Yours looks as it is not STAINLESS. Handle shape and size at times are totally redesigned. I might need to make 2 smaller knives from a large blank, I will steal from the TANG if necessary. Not able to do so with PRE drilled pin holes or cut tang Thank youNow it is all starting to make sense but will you still have to shape the tang for the handle after they have been polished and what will dictate the handle shape/size that it couldnt be done before polishing?

View attachment 63896