Randy Lucius

Well-Known Member

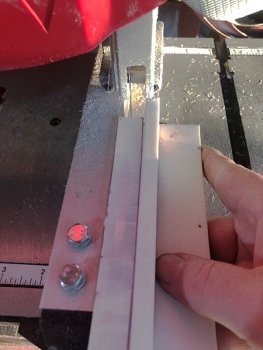

I came in from the shop to supper last night and was gripping and complaining about my tabletop band saw. It's just a cheap piece of junk. Constantly tinkering and adjusting to get it cut a half-way decent straight line. I told the wife I was about ready to take a sledge hammer to it. She said "Oh, hush. You made enough money on knives this week. Go buy you a better one."

Hey, I might just do that. Anybody have any recommendations on a decent one or are they all junk?

Hey, I might just do that. Anybody have any recommendations on a decent one or are they all junk?