I grind them after the blade is finished and sanded to 600-800 grit. The blade shape dictates how I hold it. A spear or wharncliff shape I grind like starting the edge just tapering to disappear at the tip. A clip point I hold tip down and check the best angle with the grinder off. Start grinding at the rear of the swedge and roll the tip slowly into the wheel so the swedge gets thinner and disappears at the tip. It helps to use a tool rest to rest the blade or your hands on. Use water on your belt, if you can, to help keep it cool. I start with a 220 grit and finish between 400 and 800 depending on how the grinding is going that day. I can take a couple more photos for you if it will help.

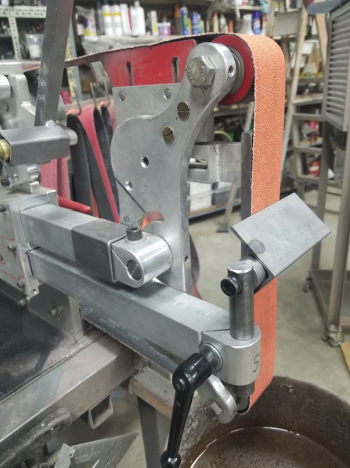

View attachment 77183