MTBob

Well-Known Member

I thought I'd show a recap of some modifications I've made to the Reeder grinder platen assembly. As a hobbyist knife maker, I enjoy making tools and modifying equipment about as much as knife making. My grinder doesn't stand the test of full time knife making, but it does get used hard for lots of other projects.

In this thread - https://knifedogs.com/threads/felt-platen-duro.53479/ - TAZ575 referenced using knobs on the adjustment arms. Stealing his idea, I decided to add that feature too.

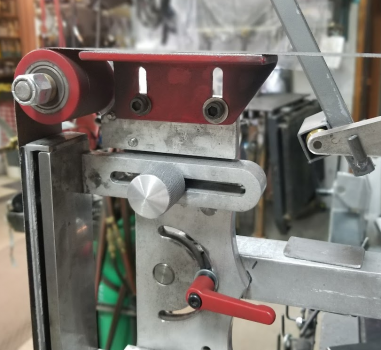

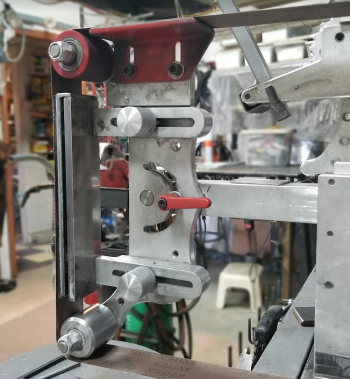

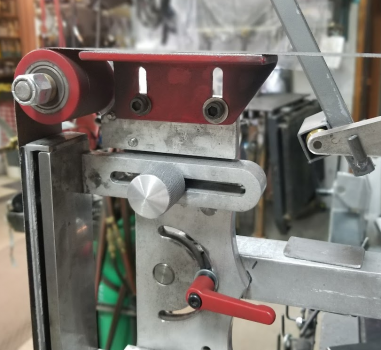

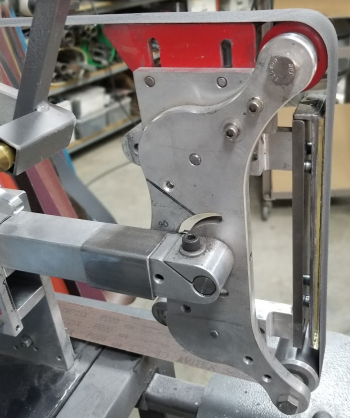

You can see in these photos the addition of a glass platen, one of several platen attachments that I use. Each one has a different thickness. So, for quick adjustment I've added two machined knurled knobs for use on the positioning arms. Using a solid rod in one hand, I can place the rod across the upper and lower wheels and platen face, loosen the adjustment arms with the other hand and quickly align the platen face to the wheels.

Notice also I've replaced the standard hex head cap screw that secures the platen rotation with an adjustable handle bolt. I suppose the adjustable handles could be used on the platen adjustment arms too. I just like the ease of using knurled knobs on low stress attachments.

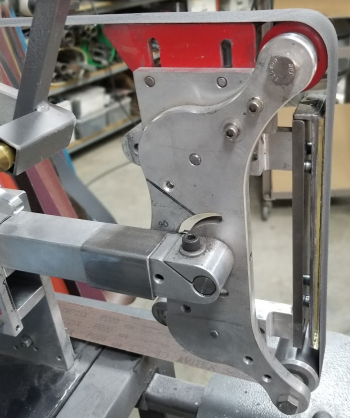

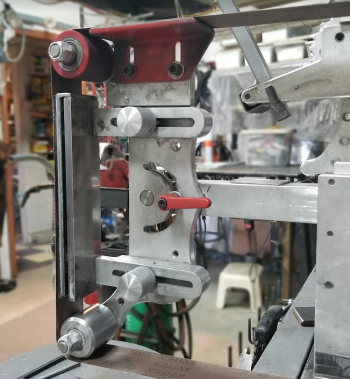

This photo shows the addition of an upper horizontal platen surface that I use for sharpening. I use this with a T Bar mounted on the lower tool arm. Having a solid surface eliminates movement in the belt and keeps the secondary angle flat and more accurately aligned. One of these days I'll do a posting showing the sharpening setup.

In this thread - https://knifedogs.com/threads/felt-platen-duro.53479/ - TAZ575 referenced using knobs on the adjustment arms. Stealing his idea, I decided to add that feature too.

You can see in these photos the addition of a glass platen, one of several platen attachments that I use. Each one has a different thickness. So, for quick adjustment I've added two machined knurled knobs for use on the positioning arms. Using a solid rod in one hand, I can place the rod across the upper and lower wheels and platen face, loosen the adjustment arms with the other hand and quickly align the platen face to the wheels.

Notice also I've replaced the standard hex head cap screw that secures the platen rotation with an adjustable handle bolt. I suppose the adjustable handles could be used on the platen adjustment arms too. I just like the ease of using knurled knobs on low stress attachments.

This photo shows the addition of an upper horizontal platen surface that I use for sharpening. I use this with a T Bar mounted on the lower tool arm. Having a solid surface eliminates movement in the belt and keeps the secondary angle flat and more accurately aligned. One of these days I'll do a posting showing the sharpening setup.