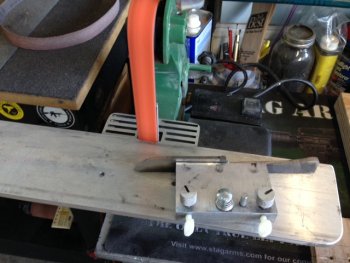

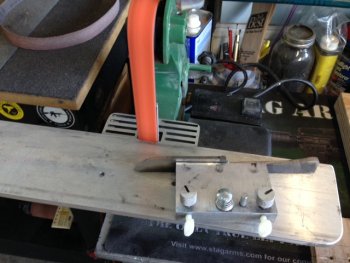

I am very new to knife making and hate to air my ignorance with simple questions, but I can't find an answer through the search function. Last week I received a few Norton blaze 1" x 30" belts and got to use them a little over the weekend. I noticed that after grinding for about an hour, they were wearing down pretty fast. Subject was an annealed file, soft enough easily drill so I assume its plenty soft. Also, quality German belts seem to wear down fast as well and all belts were routinely cleaned using a belt cleaning block.

is this normal?

is this normal?