Von Gruff

KNIFE MAKER

A few weeks back I committed to doing a road trip to the other end of the country for Lynette to visit with her sons and siblings and then decided that I would combine it with an advertising trip to see if I can get some exposure here in NZ for my knives so have a few address to call in to on the way (so I can write the expenses off as knifemaking advertising costs)

As a way to cut expenses I decided that I would convert my trailor to a sleeping pod so we could use tentsites in the camping grounds aong with thier facilities rather than paying for motels etc so our costs will go down from $100-$140 a night to about $20 a night.

I I got some 1 1/2 x 3/4 and split it is I ended up with 1 1/2 x 5/16 and laminated 3 together to make a set of hoops as a base for the roof and then split the ends of the purlins so I could bend and alminate them down over the front of the hoops to make for a wind cutting front f the trailer to compiment what was already there.

I had built the trailer many years ago as a tool mobile shed to have all my building tools when I was working away from home and with 4 ft sides and a 11ft long floor I will have plenty of room for a doube bed even though it has a tapered front the mattress wil go neary a foot into the forepeak ans leave over 4 ft at the rear for changing clothes etc or the mattress can be stood up and secured against the side so we have the full floor space.

I have got all the roof boned out so all I have to do now is lay the felt covering and the tarpaulin over it and screw the hinged back window/shutter into place.

I got the handles on the last of the knvies I want to take with me as samples, except for two I want to do to finish my kitchen set. In this batch is a JT Ranger with swamp kauri, a large horse shoe rasp bowie with brass and bluegum, a skinner with buff horn and swam kauri (for me as I think I should have something with the swamp kauri on it before it all gets used for ordered knives) , an AH big game knife with buff horn and blackwood, a general hunter with jarrah and blackwood, a hunter skinner with jarrah and rimu, and the first two (of 4) in a kitchen set with the paring knife and a salami slicer both with anged jarrah bolsters and blackwood handles. The large kitchen slicer and a kitchen cleaver are yet to be done.

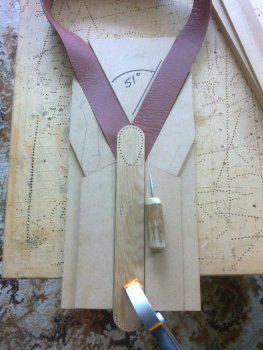

I did a short video today on how I do my knife handles when I have bolsters which I do first

As a way to cut expenses I decided that I would convert my trailor to a sleeping pod so we could use tentsites in the camping grounds aong with thier facilities rather than paying for motels etc so our costs will go down from $100-$140 a night to about $20 a night.

I I got some 1 1/2 x 3/4 and split it is I ended up with 1 1/2 x 5/16 and laminated 3 together to make a set of hoops as a base for the roof and then split the ends of the purlins so I could bend and alminate them down over the front of the hoops to make for a wind cutting front f the trailer to compiment what was already there.

I had built the trailer many years ago as a tool mobile shed to have all my building tools when I was working away from home and with 4 ft sides and a 11ft long floor I will have plenty of room for a doube bed even though it has a tapered front the mattress wil go neary a foot into the forepeak ans leave over 4 ft at the rear for changing clothes etc or the mattress can be stood up and secured against the side so we have the full floor space.

I have got all the roof boned out so all I have to do now is lay the felt covering and the tarpaulin over it and screw the hinged back window/shutter into place.

I got the handles on the last of the knvies I want to take with me as samples, except for two I want to do to finish my kitchen set. In this batch is a JT Ranger with swamp kauri, a large horse shoe rasp bowie with brass and bluegum, a skinner with buff horn and swam kauri (for me as I think I should have something with the swamp kauri on it before it all gets used for ordered knives) , an AH big game knife with buff horn and blackwood, a general hunter with jarrah and blackwood, a hunter skinner with jarrah and rimu, and the first two (of 4) in a kitchen set with the paring knife and a salami slicer both with anged jarrah bolsters and blackwood handles. The large kitchen slicer and a kitchen cleaver are yet to be done.

I did a short video today on how I do my knife handles when I have bolsters which I do first