Lerch

Well-Known Member

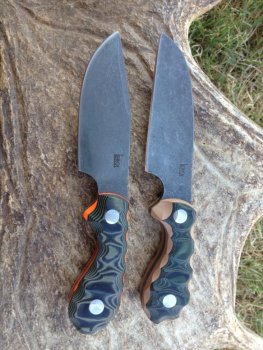

Recently i have done a couple of blades with a dark acid etch on stainless steel. I have taken these blades and ran them through my stonewash tumbler to give a nice slate look to the steel. I have had luck with a forced acid patina really improving the rust resistance of 1095 carbon steel and i was wondering if anyone thought this would also aid 440C or CPM154 with a little added rust resistance. I have a guy i am making a bird and trout knife for and i thought if i did a dark etch on the 440C it made give him a little added buffer against rust

Thanks

steve

Thanks

steve