izafireman

Well-Known Member

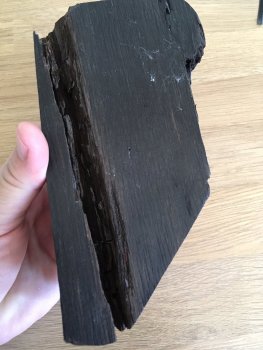

I have been asked to handle a knife with some Jet black bog .

So I cooked I first then stabilised it. The guy who sent if me is doing a collaboration with others and is sworn to secrecy as such but apparently a high end project. He is a leather worker and doing something for the project, that's as much as I know.

He asked me to impregnate the oak with copper powder as I stabilised I but on looking at the structure there was no chance , far two dense.

Now the oak has two large cracks in it so I thought about casting it in a mould and in the resin add the copper powder maybe?

I really am stuck for ideas as to what to do. What would look good with this oak?

If anyone has any ideas they would be appreciated as I really want to give this bog oak the wow factor

Cheer P

So I cooked I first then stabilised it. The guy who sent if me is doing a collaboration with others and is sworn to secrecy as such but apparently a high end project. He is a leather worker and doing something for the project, that's as much as I know.

He asked me to impregnate the oak with copper powder as I stabilised I but on looking at the structure there was no chance , far two dense.

Now the oak has two large cracks in it so I thought about casting it in a mould and in the resin add the copper powder maybe?

I really am stuck for ideas as to what to do. What would look good with this oak?

If anyone has any ideas they would be appreciated as I really want to give this bog oak the wow factor

Cheer P

:max_bytes(150000):strip_icc()/man20with20box_0-0d5d1a2afbe44ef189b5a32f427d04a6.jpg)