You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Black Walnet Handles

- Thread starter LarryJ

- Start date

NJStricker

Well-Known Member

Nothing wrong with black walnut, but most pieces don't have the heavy grain figure desired for knife handles. Usually you need to find some good dense crotch wood to get the good grain. But, if you are starting out and on a budget, use what you've got as long as it's not a super soft wood (pine, cedar, etc.). Once you get your skills down then you can move on to the more expensive woods or stabilized woods.

rhinoknives

Well-Known Member

Black Walnut has been used for centuries here in North America & Europe.

Many domestically made culinary knives have/had un-stabilized Black Walnut.

Laurence

www.rhinoknives.com

Many domestically made culinary knives have/had un-stabilized Black Walnut.

Laurence

www.rhinoknives.com

ricky_arthur

Well-Known Member

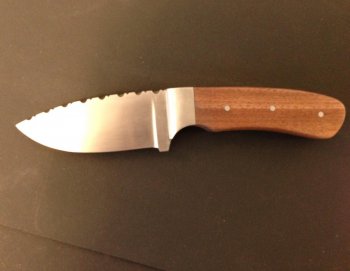

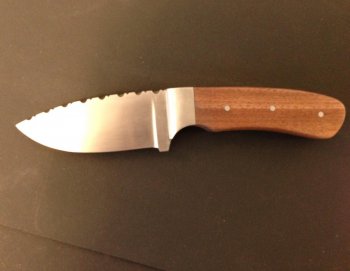

Here is one I just made out of Black Walnut. I got the Walnut from My Brother in Law, who had a pile of it sitting in his back yard. I used his chainsaw to cut a slab and then cut a few pieces out of those with a table saw. I used wood hardener in a vacuum to "stabilize" it as best I could. It doesn't have much for pattern but looks pretty good. IMO I have asked him to brine me some more when he comes in a few weeks and I guess I will see if he has any with character. He was just going to use it for fire wood.  Free is always good.

Free is always good.

Last edited:

HELLGAP

Dealer - Purveyor

No and yes gorilla super glue is used by some and find it to be an excellent glue to use for handles but some dont like the fast setting so use epoxy the slower setting the better. the stuff I use is both gorilla and G2 epoxy . Now stabilized wood can be imitated by placeing several coats of gorilla super glue over the wood and sanded lightly to leave a nice gloss finish I think there is a turtorial here in the tutorial section. Now stabilized wood is placed in a container that can recieve either pressure and or vacume to soak the wood completely through to help solidify and make the wood or ivory or horn stronger harder and polish up better. The results are amazing, I use mostly stabilized wood unless it falls in the rosewood family and they dont need to be stabilized but if they have cracks you can use super glue to fill in any bad spots same with any material. Hope this helps you out.

Peter Killgore

Well-Known Member

I think what is meant by the super glue method (at least what I call the super glue method) refers to actually using super glue as the finish on you handle. I recently did a knife with a birdseye maple handle and did a super glue finish on it. I just used original super glue, also called cyanoacrylyte (sp?). This thread http://knifedogs.com/showthread.php?26974-Scraps-from-the-Master-s-Table has some good info on doing this kind of finish. When I did it, I used an old microfiber towel to apply the super glue. Put three or four drops on a little scrap of the towel then wipe it on the handle, covering new area each time you wipe. Once you cover the whole handle, let it dry. Then just repeat until you have...oh...I think I went with ten or fifteen coats. You might need to do some light sanding along the way to knock down the high spots. The key here is light because you can sand through the super glue pretty easily. Make sure to use a high grit paper(800-1000) and have a flat hard sanding stick. This way, you'll only hit the high spots in your finish. When you're done, either buff the finish or use some carnuba wax to finish it for a nice high gloss. Here's a thread with a knife I used a black walnut handle on. http://knifedogs.com/showthread.php?6491-More-Raybar I did a teak oil finish on it. Turned out pretty nice. Post pics when you get your's done!

Peter

Peter

tHANKS for all the info guys and I also got my blank made today or my pattern. i took MIG welding welding wire to find the radius i liked and on the butt of the knife i use the bottom of a stirfoom cup for the radius. im feeling like a kid at christmas, enjoying what i got and dont know what im doing yet. now i have got to find a piece of steel i want to use for the knife. im really thinking about just an old saw blade. if or when i screw that material up i wont have any money in it.

Thanks again

Thanks again

rhinoknives

Well-Known Member

Larry,

There are so many advantages to working with a know steel. Get some, 01 or 1084/1095 if you want carbon or go with a piece of good ole 440C to make a stainless blade. If you do the 440c you can send it to me and I will batch with my stainless blades for Heat Treatment.

Laurence

www.rhinoknives.com

There are so many advantages to working with a know steel. Get some, 01 or 1084/1095 if you want carbon or go with a piece of good ole 440C to make a stainless blade. If you do the 440c you can send it to me and I will batch with my stainless blades for Heat Treatment.

Laurence

www.rhinoknives.com

Peter Killgore

Well-Known Member

I'd like to pitch in by two cents on steel too if you don't mind. I tried O-1 on a few knives and it is not a beginner steel like many say. One of the knives I did came out of the quench looking like a banana. If you can, spring for a professional heat treat on the O-1. Again, this is my two cents, which is probably about all it's worth. Good luck!

rhinoknives

Well-Known Member

The three I current use are CPM-S35VN, CPM-154 & 440C So if you use any of those I can batch it with mine for minimal cost in Heat Treatment.

Laurence

www.rhinoknives.com

Laurence

www.rhinoknives.com