Ok, since I actually started building this, I figured I'd start a new thread, so I could show pics, and get feedback, comments, advice, etc.

First off, let me say that I'm building this with the intent of using it primarily to anneal and heat treat, at least as if first get started, though given that I love just making stuff, I'm sure I'll be heating and hammering things just for giggles at some point...

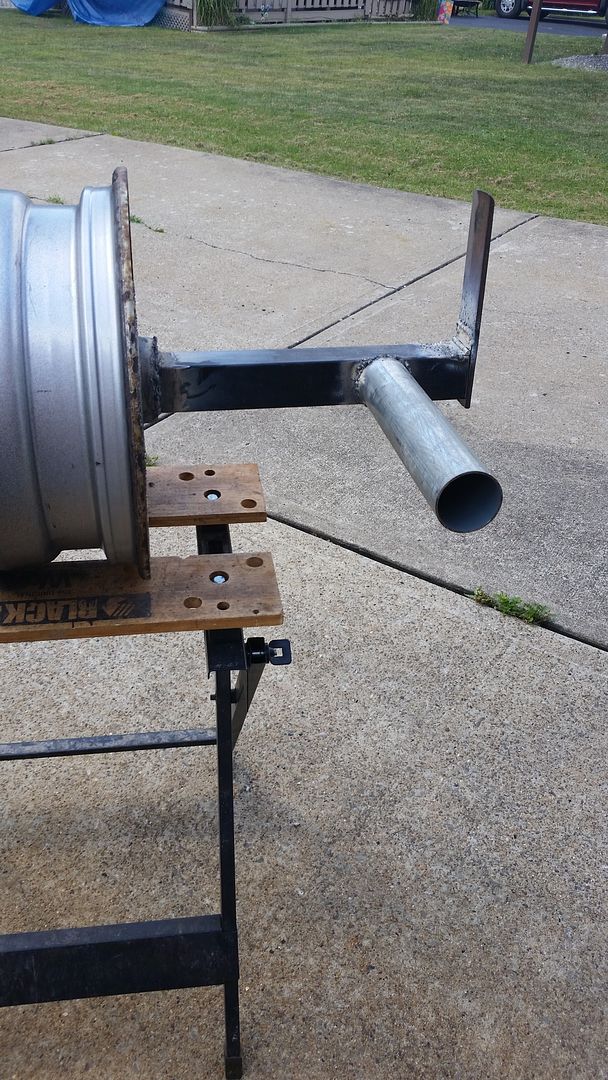

So, I dug around my scrap bin, and found this cupped washer that happened to fit nicely in the axle hole of the rim, and I thought it would keep too much fuel from falling down the hole as well as helping to distribute the air a little, so I tacked that heavily in place.

Then, I flipped the rim over, and used another piece of scrap that I salvaged from somewhere (my wife hates me, I'm forever bringing home "junk" lol) to cover the center section of the rim, and create a sorta 'manifold' to distribute airflow

then I welded on a down pipe, and an air tube.

I'd like to do something to kind of create a cone or dish shape centering on the lug holes so that there's not a lot of space sitting there holding fuel that won't be burning well because it's outside of the airflow, but right now the only sheet stock I have is light 22 or 24ga automotive sheetmetal, and I'm fairly certain that won't take the heat that I'll generate regardless of if I use charcoal, or actual coal...

On the coal note, my grandfather was a smith, and had I known then that I would want to know now, I would have learned a lot more from him, but past is past, and he's been gone for like 10 years at least... Anyhow, he used to try and find I believe it was soft coal, instead of the more readily available hard coal. (or perhaps its the reverse of that, I can't remember) But regardless, does it really matter if I would use one or the other? I havn't gotten to look and see if I can find a source for coal locally as of yet, but it's in my plans.

Anyway, comments, thoughts, and advice are all welcome.

Thanks.

First off, let me say that I'm building this with the intent of using it primarily to anneal and heat treat, at least as if first get started, though given that I love just making stuff, I'm sure I'll be heating and hammering things just for giggles at some point...

So, I dug around my scrap bin, and found this cupped washer that happened to fit nicely in the axle hole of the rim, and I thought it would keep too much fuel from falling down the hole as well as helping to distribute the air a little, so I tacked that heavily in place.

Then, I flipped the rim over, and used another piece of scrap that I salvaged from somewhere (my wife hates me, I'm forever bringing home "junk" lol) to cover the center section of the rim, and create a sorta 'manifold' to distribute airflow

then I welded on a down pipe, and an air tube.

I'd like to do something to kind of create a cone or dish shape centering on the lug holes so that there's not a lot of space sitting there holding fuel that won't be burning well because it's outside of the airflow, but right now the only sheet stock I have is light 22 or 24ga automotive sheetmetal, and I'm fairly certain that won't take the heat that I'll generate regardless of if I use charcoal, or actual coal...

On the coal note, my grandfather was a smith, and had I known then that I would want to know now, I would have learned a lot more from him, but past is past, and he's been gone for like 10 years at least... Anyhow, he used to try and find I believe it was soft coal, instead of the more readily available hard coal. (or perhaps its the reverse of that, I can't remember) But regardless, does it really matter if I would use one or the other? I havn't gotten to look and see if I can find a source for coal locally as of yet, but it's in my plans.

Anyway, comments, thoughts, and advice are all welcome.

Thanks.