yuridarian

Member

Hey guys!

Was finally able to finish another knife and a video of the process!

Didn't change my logo yet but I hope that now that I'm using electro etching and the definition is better, it will not be mistaken for something else...

Let me know what you guys think, ideas and improvements for the next ones!

Forged out of 52100 1" round stock:

Finished forging:

After profiling:

Going into the quench:

After tempering (and brainstorming on handle shape):

Knife at 150 grit and Handle wood block ready!

Ready for glue up!

Shaping the handle:

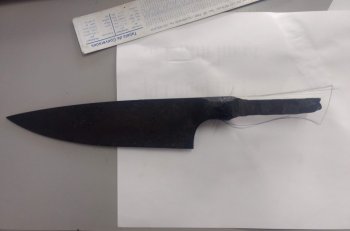

Finished knife:

There are some more detailed shots of the finished knife on the video! Check it out!

Was finally able to finish another knife and a video of the process!

Didn't change my logo yet but I hope that now that I'm using electro etching and the definition is better, it will not be mistaken for something else...

Let me know what you guys think, ideas and improvements for the next ones!

Forged out of 52100 1" round stock:

Finished forging:

After profiling:

Going into the quench:

After tempering (and brainstorming on handle shape):

Knife at 150 grit and Handle wood block ready!

Ready for glue up!

Shaping the handle:

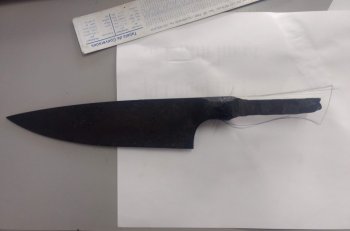

Finished knife:

There are some more detailed shots of the finished knife on the video! Check it out!

Last edited: