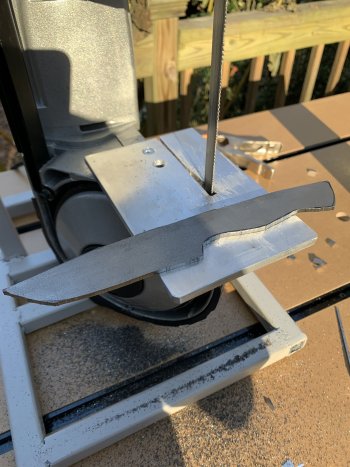

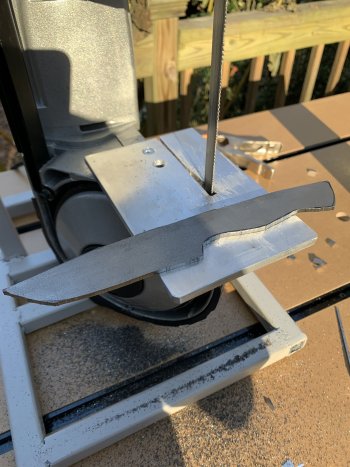

got my band saw stand done today and cut out a blank for testing purposes. Decided to do a proper WIP with it. 1/8” 1084 steel - 8.75” OAL 4” blade....biggest knife I’ve attempted. I work slow but wanted to document it all. Have olivewood for the scales and maybe some black G10 and natural micarta liners.