You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

etched steel colors

- Thread starter percy

- Start date

Freds Edge

Well-Known Member

I think you may be thinking of anodized titanium colors.

NO that is not what I am thinking. When you etch Damascus different steels have a different color shade to them that is what makes the pattern pop out. Not just the different hardness of the steel. When steels have a different hardness they look different and that is what I am asking about. Some steel look lighter and some darker because of the makeup of the steel.

J. Doyle

Dealer - Purveyor

Damascus is basically going to look black, gray or silver. Typically the silver color comes from 15n20 or maybe some powdered steel that contains nickel so it resists the acid etch.

As far as the other steels involved, I'm not sure that you can say that certain steel types etch darker than others, at least not that can be easily distinguished. Other steels are either going to look black or gray.

Hardened steel will etch darker and have more contrast that unhardened steel. How many times you etch and how long you etch each time, surface prep and etchant type and mix ratio will play a role, probably more than steel type. I've seen several different finishing methods that involve one or a combination of the following to get the non-nickel steel darker: boiling Baking soda bath, cold blue, parkerizing and baking laquers.

I've never heard it said that distinct steel types can be identified based on the color of black or gray they are when etched. There may be some that can legitimately tell, and maybe some that claim they can tell. In my experiences, w2, 1080, 1084, 1075, 80CrV2 and 1095 all appear the same color, or can be made to turn the same color when etched.

As far as the other steels involved, I'm not sure that you can say that certain steel types etch darker than others, at least not that can be easily distinguished. Other steels are either going to look black or gray.

Hardened steel will etch darker and have more contrast that unhardened steel. How many times you etch and how long you etch each time, surface prep and etchant type and mix ratio will play a role, probably more than steel type. I've seen several different finishing methods that involve one or a combination of the following to get the non-nickel steel darker: boiling Baking soda bath, cold blue, parkerizing and baking laquers.

I've never heard it said that distinct steel types can be identified based on the color of black or gray they are when etched. There may be some that can legitimately tell, and maybe some that claim they can tell. In my experiences, w2, 1080, 1084, 1075, 80CrV2 and 1095 all appear the same color, or can be made to turn the same color when etched.

I've never seen a chart. There are some basic rules however that will give you a good idea of how dark a steel will etch, based on alloy content and hardness.

Nickel content is the deciding factor in how much a steel will resist the etchant and retain its polished brightness (there are other alloys that will do the same, however they are rarely used in modern times). The higher the nickel content, the more it will resist the etch, and the brighter it will appear. Pure nickel will be the brightest of all, followed by 203e, then 15n20 and L6.

There are specific alloys that will cause the steel to appear darker, the two I am aware of are chromium and manganese, and there are likely others I am not aware of. It is safe to say that the higher the manganese content, the darker the steel will be. This is one of the reasons Aldo's 1084 is popular, it has a fairly high manganese content so gives great contrast mixed with 15n20... it is also simple to heat-treat, welds easily, and makes a fine blade. Aldo's 1095 or W2, on the other hand, will not be as dark when mixed with 15n20 because both steels have a very low manganese content. Steels with chrome also tend to etch darker, but I have not experimented much in this direction.

Now one could theoretically make a multi-tone damascus using many types of steel in a billet, but this can also lead to problems. I once had the bright idea to make damascus using 1095, 5160, and 15n20. One would expect three distinct shades when the steel was etched. Unfortunately, the two blades I made from the mix tore themselves apart in the quench due to the drastically different hardenabilities of the steels. The more comparable the steels are to one another, the better the odds are of making a viable mix, this is another reason we use 1084 and 15n20... the only real difference between the two is the nickel content. Chromium and manganese both have a large effect on the hardenability of the steel, so mixing a very high manganese steel with one with a very low content is just asking for a tragic ending in the quench. Carbon will migrate and equalize throughout the billet, but chromium and manganese will not....

Nickel content is the deciding factor in how much a steel will resist the etchant and retain its polished brightness (there are other alloys that will do the same, however they are rarely used in modern times). The higher the nickel content, the more it will resist the etch, and the brighter it will appear. Pure nickel will be the brightest of all, followed by 203e, then 15n20 and L6.

There are specific alloys that will cause the steel to appear darker, the two I am aware of are chromium and manganese, and there are likely others I am not aware of. It is safe to say that the higher the manganese content, the darker the steel will be. This is one of the reasons Aldo's 1084 is popular, it has a fairly high manganese content so gives great contrast mixed with 15n20... it is also simple to heat-treat, welds easily, and makes a fine blade. Aldo's 1095 or W2, on the other hand, will not be as dark when mixed with 15n20 because both steels have a very low manganese content. Steels with chrome also tend to etch darker, but I have not experimented much in this direction.

Now one could theoretically make a multi-tone damascus using many types of steel in a billet, but this can also lead to problems. I once had the bright idea to make damascus using 1095, 5160, and 15n20. One would expect three distinct shades when the steel was etched. Unfortunately, the two blades I made from the mix tore themselves apart in the quench due to the drastically different hardenabilities of the steels. The more comparable the steels are to one another, the better the odds are of making a viable mix, this is another reason we use 1084 and 15n20... the only real difference between the two is the nickel content. Chromium and manganese both have a large effect on the hardenability of the steel, so mixing a very high manganese steel with one with a very low content is just asking for a tragic ending in the quench. Carbon will migrate and equalize throughout the billet, but chromium and manganese will not....

Sounds like I got some good answers. I really appreciate the time you guys spent writing this. There is more of my question answered in the last two remarks and thanks a lot. I knew there was a difference in some type of color but did not know what. I did see a chart once that showed how each steel would look and some did look lighter but it could have been just a lighter gray verses a black. Either way thanks a lot for the help here.

bubba-san

Well-Known Member

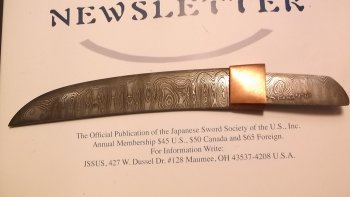

I think what you may be referring to is extended tempering after etch. This particular blade has 6 types of steel in it . I cant really see much color difference , just shades of grey and black.

But, if you do some long tempering cycles steel will change colors , like red, blue ,purple ,orange depending on the steel . The only problem I found with color treating was a slight decrease in hardness and edge holding. other than that it makes some colorful blades .......... Bubba

But, if you do some long tempering cycles steel will change colors , like red, blue ,purple ,orange depending on the steel . The only problem I found with color treating was a slight decrease in hardness and edge holding. other than that it makes some colorful blades .......... Bubba