franklin

Well-Known Member

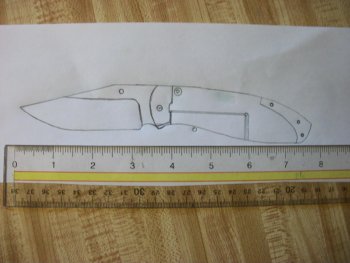

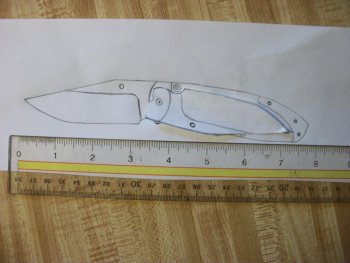

I am trying to design my first folder and this is what I came up with.

Any suggestions or critiques welcome would like to get it right

hope pics show everything. one open one closed and was thinking of using thumb stud as part of stop.

Any suggestions or critiques welcome would like to get it right

hope pics show everything. one open one closed and was thinking of using thumb stud as part of stop.