Hello folks,

I started making knives as a hobby about 2 years ago, and have been lurking here and in some other forums for quite a while and been able to find numerous threads with invaluable information so far. As I am german I mainly visit the german Messerforum.net and came only to look not to post. I found several threads about HT oven construction but no one got into detail how to make your own elements. Mostly premade ones were used. As I actually have calculated and made elements for my former homemade oven and I am currently in the process of building a bigger one right now I thought to share the method.

There already have been several tutorials on how to build an HT oven so I will not elaborate on how to build a sheetmetal box, line it with bricks and install the elements in grooves.

This is only about the elements here.

Most of these ovens are fitted with premade commercial elements, this will work fine if you choose the right oven size, element size, and power.

But premade elements may not always be available or fit the desired size of oven to be build. So here I will concentrate solely on how to design your own elements from scratch. This will work for all different sizes.

Disclaimer: All the informations on wire specs and the recommended application come from the manufacturer. Only basic electric formulas are needed . With the below stated method I have so far built two kilns and have met no problems. I am not an expert and only want to show how I do things, your mileage may vary. I will take no responsibility whatsoever if you follow these instructions. If you have no knowledge of things electric please ask an electrician first. You are hopefully all old enough to think by yourselves. Humans are prone to errors an so am I - If I did hit the wrong button on the calculator or did get something messed up in the process of writing it down please feel free to correct me. I have read this several times now but often the most obvious errors are hard to catch. As I am not a native speaker any of the spelling and grammatical errors are yours to take home and not bother me with. :biggrin: If you have any Questions please feel free to ask. I will try to answer as good as I can.

I have split this into several separate sections which are:

1. Size of the oven and required power.

2.Wire in general, How much wire of which diameter

3. Surface Load

4. Coil core diameter + Stretch factor

5. Combining multiple elements

1. Size of the oven and required power

Your first consideration should be:

1.1 Power:

-What kind of voltage is available (230V, 110V, 380V etc) and how much amperes are allowed in your household appliance system per single outlet?

Example: Where I live we have 230V and a single wall outlet permits a maximum of 16A.

U(Volt) x I(Amp)=P(Watt)

230Volts x 16 Amp = 3680Watt

So the most powerful oven I can operate from a single outlet is rated 3680W.

It is advisable to stay about 10% below this to avoid too easy triggering of the safety fuse when running the oven . This gives me about 3312W, so lets say 3300W is good and safe to operate from a single outlet here.

1.2 Size:

-What is the maximum chamber size one can operate from a given Wattage?

This depends on several factors, some being the insulation value of your kiln and desired heating rate. It should be obvious that with a 1000W element you cannot heat an oil drum sized oven up to heat treat temps.

If you are an engineer specialized in this field you can calculate the size and power requirement precisely with Insulation value and heat loss rate , desired max. temperature and heating speed, convection, radiation and conduction , mass and thermal conductivity of the objects to heat.

As I am not able to do this I had to rely on information I could get from books on pottery kilns and commercially available kilns.

The Olson Kiln book states a value of 0,92 W/cm² - 1,3W/cm² of heated wall surface. If one looks at commercial kilns, chamber size and watts are usually given. If you correlate these you will see that most of these operate in the range of 0,6 W/cm² - 1 W/cm²

Some examples below:

Evenheat kilns:

Kf18 = 0,668 W/cm²

KF22,5 = 0,639 W/cm²

Paragon kilns:

PMT10 = 0,676 W/cm²

KM24D = 1,08 W/cm²

I do not know the insulation value of these commercial kilns but I think if one uses soft ceramic firebricks the insulation value should be on par. To ease calculation and also to be on the safe side I think calculating with a value of 1 Watt per cm² of chamber surface is feasible.

Example:

My oven to be built will have a chamber size of 12,4cm x 12cm x 50cm. this is a convenient size for me to build because my bricks are 25cmx6,4cmx12,4cm. With no cutting of the bricks required I can easily get the above mentioned chamber size. Only the grooves for the elements will have to be made. Well, I am a lazy guy

Total surface area of chamber = 2737,6cm² equals 2737 Watts.

When elements age over time their diameter is shrinking due to oxidation, the resistance goes up and the power of the oven is dropping. To compensate for this and to speed up the heating rate I tend to slightly overbuild. So for this size oven I will raise to 3000Watts which is still within safe power range of the outlet and also eases calculation further on.

2.Wire in general, How much wire of which diameter

2.1 Wire

What kind of resistance wire to use?

Two of the most useful informational sources I have been able to find and most HIGHLY RECOMMENDED come from the manufacturer itself:

the “Kanthal appliance handbook”

http://www2.kanthal.com/sandvik/0971/internet/s003237.nsf/F6421C7808255963C12572BB001C8704/$file/1-A-2-3%20appliance%20handbook%20US.pdf

or the “Kanthal furnace mini Handbook”

http://hitempproducts.thomasnet.com/Asset/The-Kanthal-Furnace-Mini-Handbook---Metric-version-.pdf

these are freely downloadable from the web and contain numerous valuable Data and Graphs which are needed by the aspiring element designer later on. I will refer mostly to the furnace mini handbook because I am a metric guy, sorry folks.

In short, I recommend you use Kanthal A1 resistance wire because this is widely available in different gauges from pottery suppliers etc. and gives a long lasting element which is not operating at it`s limits with the temperatures we desire.

I have used Nicrothal80 in the past ,who`s main advantage is that it`s much cheaper, but compared to kanthal A1 wire the life expectancy at our desired temperatures is more than 300% higher for the kanthal a1 wire. (Furnace mini handbook p.8 Fig5 graph). This should make paying the higher price for kanthal easier.

You can use all the other different grades of wire mentioned like APM, D, AF, Ncr80/20 whatever you can easily and cheaply get. Some are Better like APM some are worse like nicrothal. Your elements will maybe not last as long with the lower grades but work they will - if properly designed.

You will need to have the requiredwire specs for calculation. These are all given in the aforementioned pdfs.

2.2 Wire length

How much wire of a given diameter do I need to get an element with specific Wattage?

There are two methods you can employ to calculate the needed wire length, a cruder but little simpler one which is mostly sufficient and a more refined one which gives an exacter calculation.

Method a)

So now you have figured out how much Watts your oven will need, next step is to tie this to wire length. Every resistance wire has a given resistance per diameter (these are not called resistance wire for nothing) Resistance is mostly given in Ohms/m, as I am a metric guy I will calculate metric only. You can convert all the calculations to inches/feet and use different Voltages, this will not change anything.

What we now know is :

-3000Watts needed

-230V volts supplied

What we want to know is:

-How much Ohms?

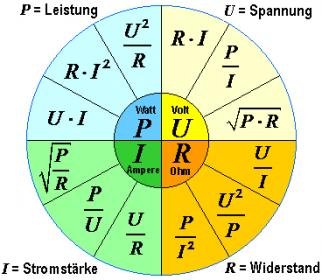

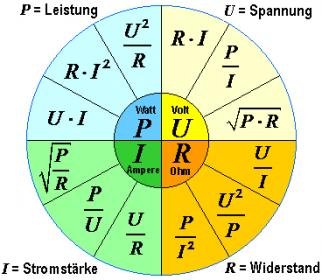

If you still can remember your school days maybe some basic electric formulas will pop up in your mind, if not the picture may help:

http://i270.photobucket.com/albums/jj104/rolynd666/formelrad/FormelradElektronik.gif

U²/P=R is the right one now

230²/3000 = 17,633 Ohms

Example:

Let`s say we have a 1mm diameter kanthal A1 wire . This is NOT the right diameter and the element will have a very short life. Why so, I will explain in the next section. Nevertheless let`s get on with this one.

If you look up the data for 1mm A1 wire in the kanthal handbook (page 19) a resistance of 1,85 Ohms per meter is given.

So now just calculate how much meters you need to get to 17,633 Ohms

17,633/1,85 = 9,53 meters

To get an element which has 3000 Watts you need 9,53m to do so.

Easy so far ,Wasn’t it

Method b)

The second method takes into consideration that the wire actually changes its resistance gradually when coming up to a specific temperature and calculates with resistivity. This gives a more accurate calculation. When you had looked at the data for A1 wire (page 19 in the kanthal mini handbook) you may have seen that above the data a smaller table with resistivity and correction values for different temperatures is given. You may have wondered what these are for – well, now you need those!

Kanthal A1 has a resistivity of 1,45 Ohms/mm² . Correction factor is 1,04 because max desired temperature would be 1100°C so total Resistivity is : 1,45x1,04 = 1,508 Ohms/mm²

The other two values you need are:

- resistance, (see2.1) = 17,633 Ohms

- crossection area of the wire diameter. In mm² please. With 1 mm diameter wire we get= 0,785mm²

Length of wire = (Ohms x wire crossection area) / Resistivity

(17,633 x 0,785)/ 1,508 = 9,18m

You see now that there is a difference of 35cm between the two methods of calculation. This equals a difference of 114,8 Watts. Because I have selected the power with a bit leeway in both directions it would be no big deal to use the first method but I prefer the second.

3. Surface Load

One of the most important things influencing the life expectancy of elements and I think a really crucial factor is the surface load.

This means nothing more than how the total watts spread over the surface area of the element. If you put too much force in too thin a wire , the wire will overheat and oxidize fast and if grossly overheated will just melt. Element destroyed ,oven kaputt.

To avoid this we must stay within a safe region of surface load. Surface load is measured in Watts/cm². the cm² being the surface area of the whole wire used. You have to keep in mind that almost all of the graphs and data given in the kanthal Handbook are based on a wire thickness of 3 mm. So this does not always directly translate to thinner wire gauges which are mostly used in small ovens like knifemaking ovens. Expect thinner wires to last not as long as 3mm wires. It would be good if we could use just 3 mm wire everywhere but this is mostly not possible.

The kanthal furnace handbook tells us on page7 that at a temperature of 1100°C the surface load should not exceed 3 W/cm² for spiral elements in grooves, which is the common employment mode we use. Freely radiating “rod over bend” elements (zigzagging w/o sharp corners) can be used with more surface load ( 5W/cm²) but have the disadvantage of taking more space and being much more complicated to install.

Please note the small script at the bottom of the graph, this is important because it tells us that when used with an on/off control (which is what a PID does) about 20% less of the given value is to be used : spiral elements = 2,4W/cm² . If you use thyristor control you can go with 3W/cm². If you remember the underlined section a few sentences before one should best be using an even lower value if using wire of less than 3mm thickness. This is what the manufacturer recommends, but you can get away with a little more. For how long? well, I dunno…

So you can imagine now why the so far designed element is not a long lived one. We will calculate the surface load now and you will see.

At first we will need the surface area of the used wire. A wire is nothing more than a very long very thin cylinder so with 9,18m and 1mm thickness we get : 2 x pi x radius x length=288,4cm² surface area . Then the Watts are divided by surface. For our 3000W 1mm element we get:

3000W/288,4cm² = 10,4 W/cm²

So far our designed element is getting almost five times the surface load that is recommended. Expect it to have a short life or maybe even fail the instant you turn the oven on the first time.

So far all our calculations have been correct but the element is not durable/usable because we selected a too small diameter wire.

The often used budgetcastingsupply premade elements have been proven to work. If I have calculated correctly they have a wire diameter of 1,45mm(15AWG) at 115v and 1550watt and so give a surface load of ca. 3,7W/cm². I would expect them to have a shorter life expectancy than a homemade one with lower surface load. If you connect two of those in series – not the best solution. If you connect them in parallel it would be much better. Why? See section 5. There is not a dramatically big difference to the kanthal recommended value so I do not know how much shorter the life will be. Obviously a good choice for people who do not want to go through the trouble of making their own ones if you have an oven that they will fit into.

How do we get to know what size of wire diameter wire we need?

Unfortunately not being a mathematical genius I have not come up with an easy to use formula which you can input all your wanted specs and it puts out a wire size and length.

If we have someone here who can do this please chime in

I still do this the hard way by calculating elements with different wire diameters until I arrive at a wire size which gives me the desired surface load. Then I check if the coiled and stetched element fits will my oven. I aim for the thickest wire that can be fitted into my oven without problems of coil size.

Well, I can`t do all the work for you so please calculate a little for yourselves. All the Methods are given above.

For my oven to build I have selected a wire diameter of 1,8mm. this gives me a surface load of 1,79W/cm². Way below requirements, should give me a long lasting element.

An 1,6mm Wire could also have been used this gives me a surface load slightly above the required 2,4 but I was able to get a length of 1,8mm Wire for a very good price

4. Coil core diameter + Stretch factor

Finally lets get to the physical outlay of the Element. This is also an important factor but not as crucial as surface load.

Again the now familiar kanthal Handbook does help here too. See page 7 and 10.

The spiral element has to have at least a coil core diameter of 5-7 times the wire thickness. Larger is no problem other than oven fit.

Also the element has to be stretched to a minimum length between the single windings. The distance between the single windings should be 2-3 times wire diameter.

This prevents the element from mostly a)overheating, b) shorting between single windings and so provides a longer service life. Especially when fitting the coiled element to curves be careful that the windings do not connect at the inside of the curve. Mostly the element will have to be stretched a little more in curves to avoid this. Also spiral elements tend to move in the grooves bunching up in one section and stretching in others because of the cycling so its advisable not to select a too small stretch factor otherwise the windings can shorten each other out and overheat in some sections over time.

If you have found out what wire diameter to use please take the time to calculate what length the element will have in coiled and properly stretched condition. You will find that the thicker the wire gets the better the surface load but this amounts to a longer and thicker element. You will soon come to a point where the element is of a size that you will have not enough space in your oven to fit the element in. Usually elements are only in the sides of the chamber so check for enough space before you make one. It would be great if we could use the really thick wire in small ovens but this does seldom work due to the space limitation.

I am getting a little weary now of calculating and think you are all able to figure out how to calculate the length of a coil essentially nothing but a series of rings with a given diameter and wire thickness…

5.Combining multiple elements

It may or may not be obvious but you are not restricted to use only one element , you can connect several elements either in serial or in parallel configuration. There are advantages and disadvantages to both methods. These do not have to be of the same Length. To avoid more confusion, in the example two equal elements are connected . I have to use two other formulas in this section but they are still basic ones.

To calculate we need three values

-Volts: We know we put 230v in the system

- Resistance:. calculate this for each element separate . We use here two of the exact same length so resistance is the same.

To calculate surface load you need surface area. Here: 288,4cm² per element used.

5.1 Serial connection:

What happens if we take our previously calculated element of 1mm Wire and connect two of those in series?

Fixed values are:

Input Voltage U = 230v.

Resistance = 17,63 Ohms per element

Surface of a single element : 288,4 cm²

What will change are Current and Power.

If resistors are connected in series the rules are:

Rx = R1 + R2 + R3…..

Rx = 17,63 + 17,63 = 35,26 Ohms

Volts are: 230V.

From these two values we calculate the Current : I= U/Rx = 6,53 Amperes

What happens to the power? : P=U x I = 1500Watts

Because we have doubled the length of the wire we have doubled the surface area so

Surface load is now also lower: 1500/576,8 = 2,6W/cm² instead of 10,4W/cm² .

So by connecting two of the same elements in series we have brought the surface load down into a Safe to use region but we have also halved the total Power. We could now use this new element but the oven would have only half the power.

5.2 Parallel connection

If resistors are connected in parallel the following applies:

1/Rx = 1/R1 + 1/R2 + 1/R3…

Two elements in parallel we get : 1/Rx = 1/17,63 + 1/17,63 = 1/0,113 ,so : Rx=8,84 Ohms

The voltage stays the same : U = 230Volts

Current : I = U/Rx = 26 Amps

Power P = U x I = 5980Watt

Surface load: 5980/576,8 =10,37 W/cm²

So connecting elements in parallel maintains the surface load but hightens the Power.

If you would use three parallel elements you would further raise the power but still maintain the same surface load.

How can we employ this now to make use of the 1mm wire?

Best way is to make a less powerful single element which has the correct surface load and then connecting several of those in parallel until the desired Power is achieved.

Lets look at a 1500W element from 1mm wire:

230V²/1500W= 35,26 Ohms

35,26/ 1,85 = 19m

At 31,4cm² per m of 1mm wire : 596,6cm²

1500/596,6= 2,5 W/cm² surface load

That we can live with.

So if you connect two 1500W elements in parallel you get approx 6000W with an acceptable surface load. as this is still too high use lower wattage elements /different wire diameter till the desired power is at your needs - or build a bigger oven!

I hope this was helpful to some of you, please enjoy.

I started making knives as a hobby about 2 years ago, and have been lurking here and in some other forums for quite a while and been able to find numerous threads with invaluable information so far. As I am german I mainly visit the german Messerforum.net and came only to look not to post. I found several threads about HT oven construction but no one got into detail how to make your own elements. Mostly premade ones were used. As I actually have calculated and made elements for my former homemade oven and I am currently in the process of building a bigger one right now I thought to share the method.

There already have been several tutorials on how to build an HT oven so I will not elaborate on how to build a sheetmetal box, line it with bricks and install the elements in grooves.

This is only about the elements here.

Most of these ovens are fitted with premade commercial elements, this will work fine if you choose the right oven size, element size, and power.

But premade elements may not always be available or fit the desired size of oven to be build. So here I will concentrate solely on how to design your own elements from scratch. This will work for all different sizes.

Disclaimer: All the informations on wire specs and the recommended application come from the manufacturer. Only basic electric formulas are needed . With the below stated method I have so far built two kilns and have met no problems. I am not an expert and only want to show how I do things, your mileage may vary. I will take no responsibility whatsoever if you follow these instructions. If you have no knowledge of things electric please ask an electrician first. You are hopefully all old enough to think by yourselves. Humans are prone to errors an so am I - If I did hit the wrong button on the calculator or did get something messed up in the process of writing it down please feel free to correct me. I have read this several times now but often the most obvious errors are hard to catch. As I am not a native speaker any of the spelling and grammatical errors are yours to take home and not bother me with. :biggrin: If you have any Questions please feel free to ask. I will try to answer as good as I can.

I have split this into several separate sections which are:

1. Size of the oven and required power.

2.Wire in general, How much wire of which diameter

3. Surface Load

4. Coil core diameter + Stretch factor

5. Combining multiple elements

1. Size of the oven and required power

Your first consideration should be:

1.1 Power:

-What kind of voltage is available (230V, 110V, 380V etc) and how much amperes are allowed in your household appliance system per single outlet?

Example: Where I live we have 230V and a single wall outlet permits a maximum of 16A.

U(Volt) x I(Amp)=P(Watt)

230Volts x 16 Amp = 3680Watt

So the most powerful oven I can operate from a single outlet is rated 3680W.

It is advisable to stay about 10% below this to avoid too easy triggering of the safety fuse when running the oven . This gives me about 3312W, so lets say 3300W is good and safe to operate from a single outlet here.

1.2 Size:

-What is the maximum chamber size one can operate from a given Wattage?

This depends on several factors, some being the insulation value of your kiln and desired heating rate. It should be obvious that with a 1000W element you cannot heat an oil drum sized oven up to heat treat temps.

If you are an engineer specialized in this field you can calculate the size and power requirement precisely with Insulation value and heat loss rate , desired max. temperature and heating speed, convection, radiation and conduction , mass and thermal conductivity of the objects to heat.

As I am not able to do this I had to rely on information I could get from books on pottery kilns and commercially available kilns.

The Olson Kiln book states a value of 0,92 W/cm² - 1,3W/cm² of heated wall surface. If one looks at commercial kilns, chamber size and watts are usually given. If you correlate these you will see that most of these operate in the range of 0,6 W/cm² - 1 W/cm²

Some examples below:

Evenheat kilns:

Kf18 = 0,668 W/cm²

KF22,5 = 0,639 W/cm²

Paragon kilns:

PMT10 = 0,676 W/cm²

KM24D = 1,08 W/cm²

I do not know the insulation value of these commercial kilns but I think if one uses soft ceramic firebricks the insulation value should be on par. To ease calculation and also to be on the safe side I think calculating with a value of 1 Watt per cm² of chamber surface is feasible.

Example:

My oven to be built will have a chamber size of 12,4cm x 12cm x 50cm. this is a convenient size for me to build because my bricks are 25cmx6,4cmx12,4cm. With no cutting of the bricks required I can easily get the above mentioned chamber size. Only the grooves for the elements will have to be made. Well, I am a lazy guy

Total surface area of chamber = 2737,6cm² equals 2737 Watts.

When elements age over time their diameter is shrinking due to oxidation, the resistance goes up and the power of the oven is dropping. To compensate for this and to speed up the heating rate I tend to slightly overbuild. So for this size oven I will raise to 3000Watts which is still within safe power range of the outlet and also eases calculation further on.

2.Wire in general, How much wire of which diameter

2.1 Wire

What kind of resistance wire to use?

Two of the most useful informational sources I have been able to find and most HIGHLY RECOMMENDED come from the manufacturer itself:

the “Kanthal appliance handbook”

http://www2.kanthal.com/sandvik/0971/internet/s003237.nsf/F6421C7808255963C12572BB001C8704/$file/1-A-2-3%20appliance%20handbook%20US.pdf

or the “Kanthal furnace mini Handbook”

http://hitempproducts.thomasnet.com/Asset/The-Kanthal-Furnace-Mini-Handbook---Metric-version-.pdf

these are freely downloadable from the web and contain numerous valuable Data and Graphs which are needed by the aspiring element designer later on. I will refer mostly to the furnace mini handbook because I am a metric guy, sorry folks.

In short, I recommend you use Kanthal A1 resistance wire because this is widely available in different gauges from pottery suppliers etc. and gives a long lasting element which is not operating at it`s limits with the temperatures we desire.

I have used Nicrothal80 in the past ,who`s main advantage is that it`s much cheaper, but compared to kanthal A1 wire the life expectancy at our desired temperatures is more than 300% higher for the kanthal a1 wire. (Furnace mini handbook p.8 Fig5 graph). This should make paying the higher price for kanthal easier.

You can use all the other different grades of wire mentioned like APM, D, AF, Ncr80/20 whatever you can easily and cheaply get. Some are Better like APM some are worse like nicrothal. Your elements will maybe not last as long with the lower grades but work they will - if properly designed.

You will need to have the requiredwire specs for calculation. These are all given in the aforementioned pdfs.

2.2 Wire length

How much wire of a given diameter do I need to get an element with specific Wattage?

There are two methods you can employ to calculate the needed wire length, a cruder but little simpler one which is mostly sufficient and a more refined one which gives an exacter calculation.

Method a)

So now you have figured out how much Watts your oven will need, next step is to tie this to wire length. Every resistance wire has a given resistance per diameter (these are not called resistance wire for nothing) Resistance is mostly given in Ohms/m, as I am a metric guy I will calculate metric only. You can convert all the calculations to inches/feet and use different Voltages, this will not change anything.

What we now know is :

-3000Watts needed

-230V volts supplied

What we want to know is:

-How much Ohms?

If you still can remember your school days maybe some basic electric formulas will pop up in your mind, if not the picture may help:

http://i270.photobucket.com/albums/jj104/rolynd666/formelrad/FormelradElektronik.gif

U²/P=R is the right one now

230²/3000 = 17,633 Ohms

Example:

Let`s say we have a 1mm diameter kanthal A1 wire . This is NOT the right diameter and the element will have a very short life. Why so, I will explain in the next section. Nevertheless let`s get on with this one.

If you look up the data for 1mm A1 wire in the kanthal handbook (page 19) a resistance of 1,85 Ohms per meter is given.

So now just calculate how much meters you need to get to 17,633 Ohms

17,633/1,85 = 9,53 meters

To get an element which has 3000 Watts you need 9,53m to do so.

Easy so far ,Wasn’t it

Method b)

The second method takes into consideration that the wire actually changes its resistance gradually when coming up to a specific temperature and calculates with resistivity. This gives a more accurate calculation. When you had looked at the data for A1 wire (page 19 in the kanthal mini handbook) you may have seen that above the data a smaller table with resistivity and correction values for different temperatures is given. You may have wondered what these are for – well, now you need those!

Kanthal A1 has a resistivity of 1,45 Ohms/mm² . Correction factor is 1,04 because max desired temperature would be 1100°C so total Resistivity is : 1,45x1,04 = 1,508 Ohms/mm²

The other two values you need are:

- resistance, (see2.1) = 17,633 Ohms

- crossection area of the wire diameter. In mm² please. With 1 mm diameter wire we get= 0,785mm²

Length of wire = (Ohms x wire crossection area) / Resistivity

(17,633 x 0,785)/ 1,508 = 9,18m

You see now that there is a difference of 35cm between the two methods of calculation. This equals a difference of 114,8 Watts. Because I have selected the power with a bit leeway in both directions it would be no big deal to use the first method but I prefer the second.

3. Surface Load

One of the most important things influencing the life expectancy of elements and I think a really crucial factor is the surface load.

This means nothing more than how the total watts spread over the surface area of the element. If you put too much force in too thin a wire , the wire will overheat and oxidize fast and if grossly overheated will just melt. Element destroyed ,oven kaputt.

To avoid this we must stay within a safe region of surface load. Surface load is measured in Watts/cm². the cm² being the surface area of the whole wire used. You have to keep in mind that almost all of the graphs and data given in the kanthal Handbook are based on a wire thickness of 3 mm. So this does not always directly translate to thinner wire gauges which are mostly used in small ovens like knifemaking ovens. Expect thinner wires to last not as long as 3mm wires. It would be good if we could use just 3 mm wire everywhere but this is mostly not possible.

The kanthal furnace handbook tells us on page7 that at a temperature of 1100°C the surface load should not exceed 3 W/cm² for spiral elements in grooves, which is the common employment mode we use. Freely radiating “rod over bend” elements (zigzagging w/o sharp corners) can be used with more surface load ( 5W/cm²) but have the disadvantage of taking more space and being much more complicated to install.

Please note the small script at the bottom of the graph, this is important because it tells us that when used with an on/off control (which is what a PID does) about 20% less of the given value is to be used : spiral elements = 2,4W/cm² . If you use thyristor control you can go with 3W/cm². If you remember the underlined section a few sentences before one should best be using an even lower value if using wire of less than 3mm thickness. This is what the manufacturer recommends, but you can get away with a little more. For how long? well, I dunno…

So you can imagine now why the so far designed element is not a long lived one. We will calculate the surface load now and you will see.

At first we will need the surface area of the used wire. A wire is nothing more than a very long very thin cylinder so with 9,18m and 1mm thickness we get : 2 x pi x radius x length=288,4cm² surface area . Then the Watts are divided by surface. For our 3000W 1mm element we get:

3000W/288,4cm² = 10,4 W/cm²

So far our designed element is getting almost five times the surface load that is recommended. Expect it to have a short life or maybe even fail the instant you turn the oven on the first time.

So far all our calculations have been correct but the element is not durable/usable because we selected a too small diameter wire.

The often used budgetcastingsupply premade elements have been proven to work. If I have calculated correctly they have a wire diameter of 1,45mm(15AWG) at 115v and 1550watt and so give a surface load of ca. 3,7W/cm². I would expect them to have a shorter life expectancy than a homemade one with lower surface load. If you connect two of those in series – not the best solution. If you connect them in parallel it would be much better. Why? See section 5. There is not a dramatically big difference to the kanthal recommended value so I do not know how much shorter the life will be. Obviously a good choice for people who do not want to go through the trouble of making their own ones if you have an oven that they will fit into.

How do we get to know what size of wire diameter wire we need?

Unfortunately not being a mathematical genius I have not come up with an easy to use formula which you can input all your wanted specs and it puts out a wire size and length.

If we have someone here who can do this please chime in

I still do this the hard way by calculating elements with different wire diameters until I arrive at a wire size which gives me the desired surface load. Then I check if the coiled and stetched element fits will my oven. I aim for the thickest wire that can be fitted into my oven without problems of coil size.

Well, I can`t do all the work for you so please calculate a little for yourselves. All the Methods are given above.

For my oven to build I have selected a wire diameter of 1,8mm. this gives me a surface load of 1,79W/cm². Way below requirements, should give me a long lasting element.

An 1,6mm Wire could also have been used this gives me a surface load slightly above the required 2,4 but I was able to get a length of 1,8mm Wire for a very good price

4. Coil core diameter + Stretch factor

Finally lets get to the physical outlay of the Element. This is also an important factor but not as crucial as surface load.

Again the now familiar kanthal Handbook does help here too. See page 7 and 10.

The spiral element has to have at least a coil core diameter of 5-7 times the wire thickness. Larger is no problem other than oven fit.

Also the element has to be stretched to a minimum length between the single windings. The distance between the single windings should be 2-3 times wire diameter.

This prevents the element from mostly a)overheating, b) shorting between single windings and so provides a longer service life. Especially when fitting the coiled element to curves be careful that the windings do not connect at the inside of the curve. Mostly the element will have to be stretched a little more in curves to avoid this. Also spiral elements tend to move in the grooves bunching up in one section and stretching in others because of the cycling so its advisable not to select a too small stretch factor otherwise the windings can shorten each other out and overheat in some sections over time.

If you have found out what wire diameter to use please take the time to calculate what length the element will have in coiled and properly stretched condition. You will find that the thicker the wire gets the better the surface load but this amounts to a longer and thicker element. You will soon come to a point where the element is of a size that you will have not enough space in your oven to fit the element in. Usually elements are only in the sides of the chamber so check for enough space before you make one. It would be great if we could use the really thick wire in small ovens but this does seldom work due to the space limitation.

I am getting a little weary now of calculating and think you are all able to figure out how to calculate the length of a coil essentially nothing but a series of rings with a given diameter and wire thickness…

5.Combining multiple elements

It may or may not be obvious but you are not restricted to use only one element , you can connect several elements either in serial or in parallel configuration. There are advantages and disadvantages to both methods. These do not have to be of the same Length. To avoid more confusion, in the example two equal elements are connected . I have to use two other formulas in this section but they are still basic ones.

To calculate we need three values

-Volts: We know we put 230v in the system

- Resistance:. calculate this for each element separate . We use here two of the exact same length so resistance is the same.

To calculate surface load you need surface area. Here: 288,4cm² per element used.

5.1 Serial connection:

What happens if we take our previously calculated element of 1mm Wire and connect two of those in series?

Fixed values are:

Input Voltage U = 230v.

Resistance = 17,63 Ohms per element

Surface of a single element : 288,4 cm²

What will change are Current and Power.

If resistors are connected in series the rules are:

Rx = R1 + R2 + R3…..

Rx = 17,63 + 17,63 = 35,26 Ohms

Volts are: 230V.

From these two values we calculate the Current : I= U/Rx = 6,53 Amperes

What happens to the power? : P=U x I = 1500Watts

Because we have doubled the length of the wire we have doubled the surface area so

Surface load is now also lower: 1500/576,8 = 2,6W/cm² instead of 10,4W/cm² .

So by connecting two of the same elements in series we have brought the surface load down into a Safe to use region but we have also halved the total Power. We could now use this new element but the oven would have only half the power.

5.2 Parallel connection

If resistors are connected in parallel the following applies:

1/Rx = 1/R1 + 1/R2 + 1/R3…

Two elements in parallel we get : 1/Rx = 1/17,63 + 1/17,63 = 1/0,113 ,so : Rx=8,84 Ohms

The voltage stays the same : U = 230Volts

Current : I = U/Rx = 26 Amps

Power P = U x I = 5980Watt

Surface load: 5980/576,8 =10,37 W/cm²

So connecting elements in parallel maintains the surface load but hightens the Power.

If you would use three parallel elements you would further raise the power but still maintain the same surface load.

How can we employ this now to make use of the 1mm wire?

Best way is to make a less powerful single element which has the correct surface load and then connecting several of those in parallel until the desired Power is achieved.

Lets look at a 1500W element from 1mm wire:

230V²/1500W= 35,26 Ohms

35,26/ 1,85 = 19m

At 31,4cm² per m of 1mm wire : 596,6cm²

1500/596,6= 2,5 W/cm² surface load

That we can live with.

So if you connect two 1500W elements in parallel you get approx 6000W with an acceptable surface load. as this is still too high use lower wattage elements /different wire diameter till the desired power is at your needs - or build a bigger oven!

I hope this was helpful to some of you, please enjoy.

Last edited: