Goot

Well-Known Member

I have a chef friend/potential client who is designing a honesuki with me, and asked for a 70/30 grind, but I've only made symmetrical secondary bevels before.

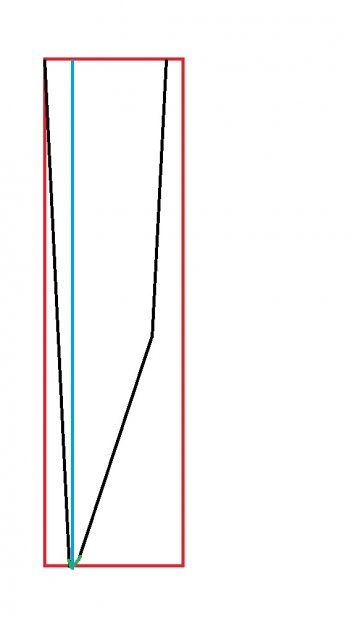

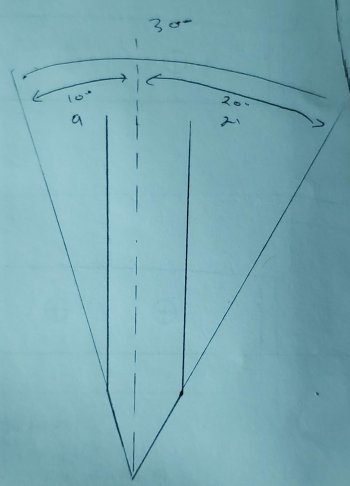

I understand what he's referring to, but I'm not sure how to start grinding and finally sharpening once the knife is done. Do I scribe a centerline that isn't centered? Is one side more convex? Do I just grind a 17 degree edge more on one side than the other, eyeballing it and then nodding if he asks I accomplished what he asked for? Isn't there some type of measurement I should be using? I can't seem to find a YouTube video that shows the process.

I'm not sure if he knows what he wants either, because he told me he wants a single bevel, but when I asked him about the urasuke he responded with "70/30", which is actually an asymmetric double bevel... shrug...

I understand what he's referring to, but I'm not sure how to start grinding and finally sharpening once the knife is done. Do I scribe a centerline that isn't centered? Is one side more convex? Do I just grind a 17 degree edge more on one side than the other, eyeballing it and then nodding if he asks I accomplished what he asked for? Isn't there some type of measurement I should be using? I can't seem to find a YouTube video that shows the process.

I'm not sure if he knows what he wants either, because he told me he wants a single bevel, but when I asked him about the urasuke he responded with "70/30", which is actually an asymmetric double bevel... shrug...