mike miller

KNIFE MAKER

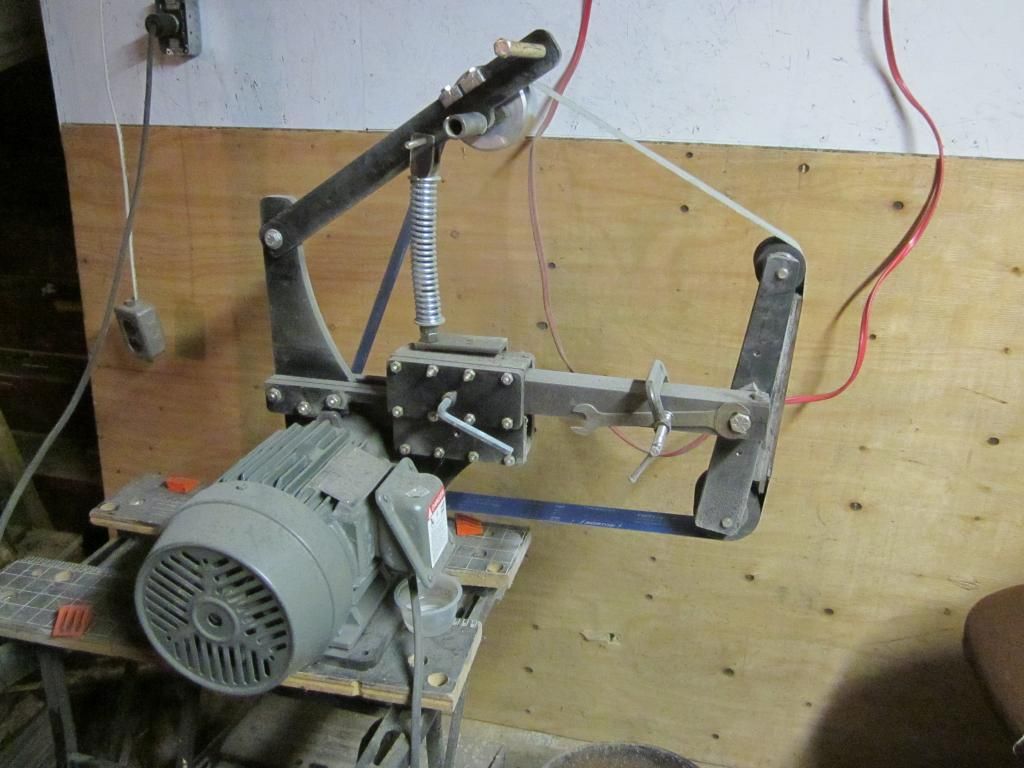

My grinder

Everything doesn't have to be flat ground. I have been using this grinder for the last 5 years for hollow grinding. It was originally built by Rick Menefee but I had to slow it downtown be better able to control it. 18 inch wheel and idler made of wood. It is smooth running.

Everything doesn't have to be flat ground. I have been using this grinder for the last 5 years for hollow grinding. It was originally built by Rick Menefee but I had to slow it downtown be better able to control it. 18 inch wheel and idler made of wood. It is smooth running.