Ryan Minchew

Well-Known Member

Howdy gentlemen. Ive been playing around with trying to make a lockback and Im having a heck of a time. I have the "How to Make Folding Knives" with Lake, Clay, Centofante and I also have "The Lockback Folding Knife From Design to completion".

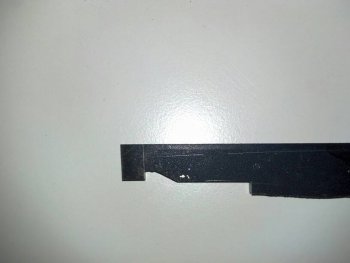

Ive beem following the Ron Lake method the most. Ive got the knife and lockbar back and ive been attempting to mock up all day. Once i get it set up and acting as a knife, i can easily push down on the blade and make the blade close with no real effort. The only way i can stop this from happening is to put so much preload on the spring that you cannotnpress the lock bar to release the knife ive tried piano wire and the square wire the normal supply houses carry. I can get the lock bar and blade to stick together no issues like several examples in the two books show. At first i had a bronze bushing that did not spin in the blade with a 1/8" pivot. This left the back of the lock right even with the back of the 1/8" pivot. I knocked the bushing out and used a 3/16" pivot trying to move the back of the lock towards the center of the pivot. Either way when i assemble the knife I can easily override the lock. I am going to attatch some pictures to see if anyone sees anything wrong. Thanks in advance for any clues or help

Ive beem following the Ron Lake method the most. Ive got the knife and lockbar back and ive been attempting to mock up all day. Once i get it set up and acting as a knife, i can easily push down on the blade and make the blade close with no real effort. The only way i can stop this from happening is to put so much preload on the spring that you cannotnpress the lock bar to release the knife ive tried piano wire and the square wire the normal supply houses carry. I can get the lock bar and blade to stick together no issues like several examples in the two books show. At first i had a bronze bushing that did not spin in the blade with a 1/8" pivot. This left the back of the lock right even with the back of the 1/8" pivot. I knocked the bushing out and used a 3/16" pivot trying to move the back of the lock towards the center of the pivot. Either way when i assemble the knife I can easily override the lock. I am going to attatch some pictures to see if anyone sees anything wrong. Thanks in advance for any clues or help