You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

makers mark poll

- Thread starter Smallshop

- Start date

Smallshop

KNIFE MAKER

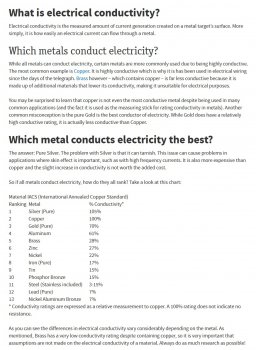

You all probably know this but it is news to me lol....Steel is 15% conductive while aluminum is 61% conductive and (the standard...not zero resistance)copper is 100%!!! I am going to make my conductor plate and screw out of either copper or aluminum. Would this mean that if you were having a tough time etching and changed to copper the quality and time taken would improve?

bladegrinder

Well-Known Member

I know for an electrical service entrance cable, aluminum is doubled in size...4/0 versus 2/0 copper but aluminum cost less.

Here's an interesting "rumer - fact", up to 500 oz. of silver are blown to smithereens with every Tomahawk cruise missile launch.

Here's an interesting "rumer - fact", up to 500 oz. of silver are blown to smithereens with every Tomahawk cruise missile launch.

Gliden07

Well-Known Member

I made mine out of a Brass screw, piece of 3/8" thick Brass guard material and a plastic handle from a garden shovel I cut off. Figured since I was going to use salt water as an etching solution and most Sea worthy boats use either Brass or SS for fittings due to the salt water (plus I had it) it would work fine? Still have to put etcher all together but I have most of what I need just need to find the right size tool box to enclose it all.

Last edited:

Smallshop

KNIFE MAKER

That looks good....brass is almost double the conductivity of steel...but only about a third of aluminum. Still...much better than steel...and the personalizers use steel.I made mine out of a Brass screw, piece of 3/8" thick Brass guard material and a plastic handle from a garden shovel I cut off. Figured since I was going to use salt water as an etching solution and most Sea worthy boats use either Brass or SS for fittings due to the salt water (plus I had it) it would work fine? Still have to put etcher all together but I have most of what I need just need to find the right size tool box to enclose it all.

View attachment 62131 View attachment 62132

The conductor plate is normally made from either brass or copper - not sure you'll ever know any difference in etching. Yes, copper has more conductivity, but brass doesn't really have that much resistance either so it will work just fine.

Ted - got the sample today, starting to work on making a stencil this afternoon.

Ted - got the sample today, starting to work on making a stencil this afternoon.

Smallshop

KNIFE MAKER

The conductor plate is normally made from either brass or copper - not sure you'll ever know any difference in etching. Yes, copper has more conductivity, but brass doesn't really have that much resistance either so it will work just fine.

Ted - got the sample today, starting to work on making a stencil this afternoon.

good! what I found was the exposure can be much longer...then I took a very soft small artists brush and snipped it short to stiffen it (do at your own discretion) and then used reading glasses to see well and "scrub" any emulsion away that didn't belong. I think the extra exposure sets it up firmer so you can clean a bit more aggressively.

I have some hi-rez coming!

Last edited:

I've got a sample sitting in the sunlight now - leaving it for 10 minutes to see how it works. I've got a brush ready to rub emulsion away. Boy, is it hard to tell shiny side from dull side! Not at all sure I can tell the difference between dull 'n shiny side.

Last edited:

Smallshop

KNIFE MAKER

I couldn't either....till after I printed on the wrong side...The emulsion is thicker on one side of the mesh than the other (as you have noticed)I've got a sample sitting in the sunlight now - leaving it for 10 minutes to see how it works. I've got a brush ready to rub emulsion away. Boy, is it hard to tell shiny side from dull side! Not at all sure I can tell the difference between dull 'n shiny side.

Gliden07

Well-Known Member

Ya know that the small commercial stencils units use a UV lamp. You could probably use a cheap Black Light lamp their UV? I'e seen them in stores for .99 cents! I will say one thing about them they get hot. Ken you could probably use that set up you have with the Black Light lamp to improve the exposure?

Smallshop

KNIFE MAKER

I don't think you want intensity. I had that first stencil too close to the light...it seemed to lose edge "crispness" and I believe it was due to light bleeding through where I didn't want it. I think a softer light for longer exposure is much better...then your mask can keep a nice sharp edge.

Jmo....

Jmo....

Ted, how long are your exposures for a good stencil? My lamp is providing too much heat - the film gets pretty hot with only 10 minutes of exposure. I tried 20 minutes, but the glass wasn't holding the template down tight and allowed too much light to bleed around the edges messing up the stencil. I am getting the emulsion side up - I can tell this because where the emulsion is washed off to leave letters, they are on the right side. Now I think the hi-res stuff will be better. This 110 thread count allows the large space between threads and not sure the etch will be clean in the spaces between threads.

Smallshop

KNIFE MAKER

My best exposure was 15 minutes under a 100w equivalent(LED) 12" inches away. I do agree the thread count is some of the resolution problem. Since I printed right on the emulsion I think it helps keep light from getting around the transparency. That 1/8 inch or so of glass can bring its own issues. by printing directly on the stencil flatness is not an issue when exposing (within reason of course). I could see thread pattern on my etch. BUT...I had so much going wrong that I didn't think of my results as much more than an excited fool rushing into where he didn't really belong....

Last edited: