Brad Walker

Well-Known Member

Happy Monday!! Short version: I would love to see your set-up for gluing multi-part handles together.

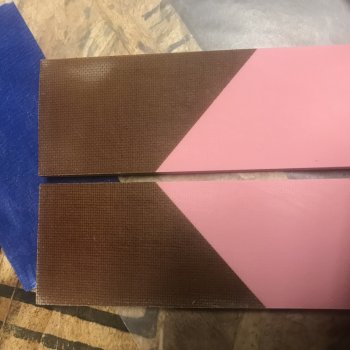

The story behind the question. So I tried my first multi-part handle using some scrap handle material I had. I was actually please with how it looked when I got done. However, I ended up with gaps on the end. I laid the pieces on another scale wrapped in wax paper. The small pieces of liner were sticking out on both sides so I'm really not sure what I did wrong. They appeared when I sanded the edges. I could dig out the epoxy but it was too deep to salvage due to how much reshaping I would have to do to the blade. Wide open to suggestions and comments I love the look so this is something I definitely plan to do more of in the near future.

The story behind the question. So I tried my first multi-part handle using some scrap handle material I had. I was actually please with how it looked when I got done. However, I ended up with gaps on the end. I laid the pieces on another scale wrapped in wax paper. The small pieces of liner were sticking out on both sides so I'm really not sure what I did wrong. They appeared when I sanded the edges. I could dig out the epoxy but it was too deep to salvage due to how much reshaping I would have to do to the blade. Wide open to suggestions and comments I love the look so this is something I definitely plan to do more of in the near future.